Products

•

April 12, 2023

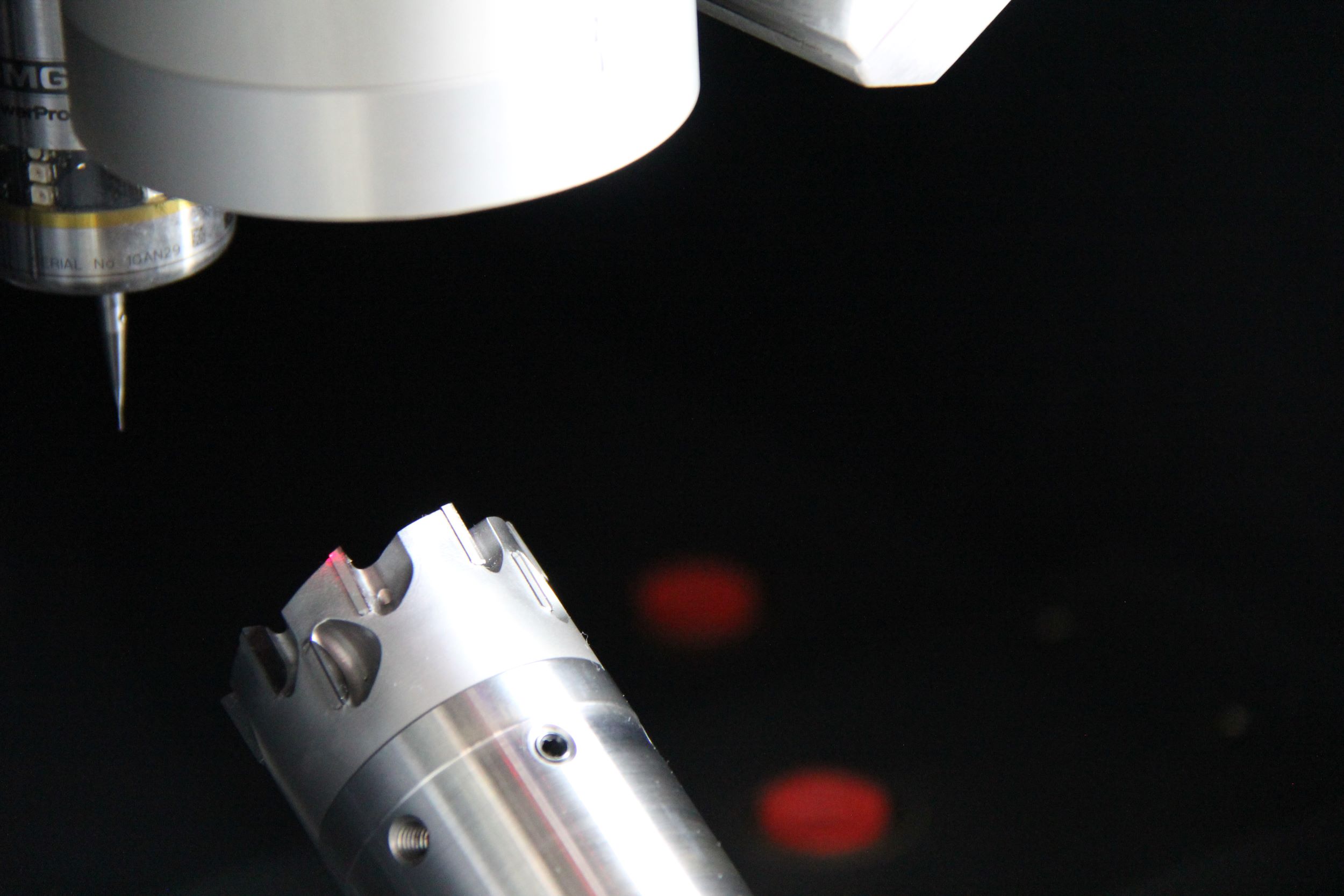

DR Reaming System

As with other tool systems, high-performance reaming systems are also subject to demanding requirements. In addition to high process reliability, long tool life and low tool costs, modern reaming tools must fulfil further criteria. These include, among other things, the modularity of the tools. While machining with an HSS reamer is partially limited in this respect, modern reaming systems can be improved by replaceable heads with carbide inserts, modular tool lengths and various adjustment options. These include, for example, µ-accurate adjustment of concentricity and runout. Precise concentricity of the reaming inserts is the path to success. In practice, this should be within 5 µm.