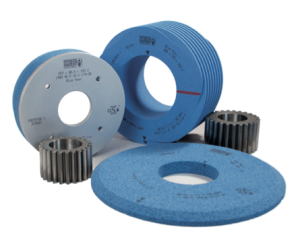

Blue Moon TZ High-Performance Grinding Wheels

The abrasive grain used in the Blue Moon TZ is very sharp-edged, microcrystalline and has an elongated trapezoidal rod shape. Blue Moon TZ grinding wheels are particularly impressive due to their very low thermal load in the contact zone. The high profile retention of our grit combination leads to extended dressing intervals at high stock removal rates and increases economic efficiency.