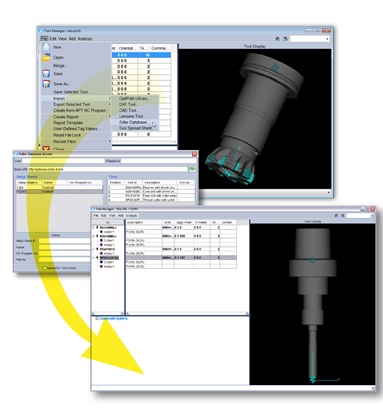

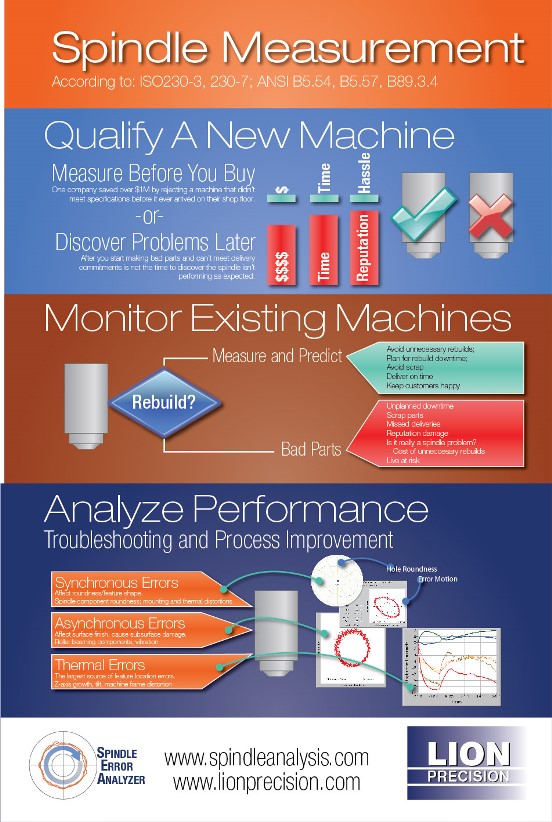

Check spindles on the machine

Thermal drift is the biggest contributor to machining and part errors. SpindleCheck from Lion Precision measures changes in the point of machining as the spindle warms up, as chillers run and as the environment changes. Precise warm-up times can be determined for each machine tool and sources of thermal drift can be identified. This is the only method that tests thermal effects at the point of machining, reports Lion Precision.