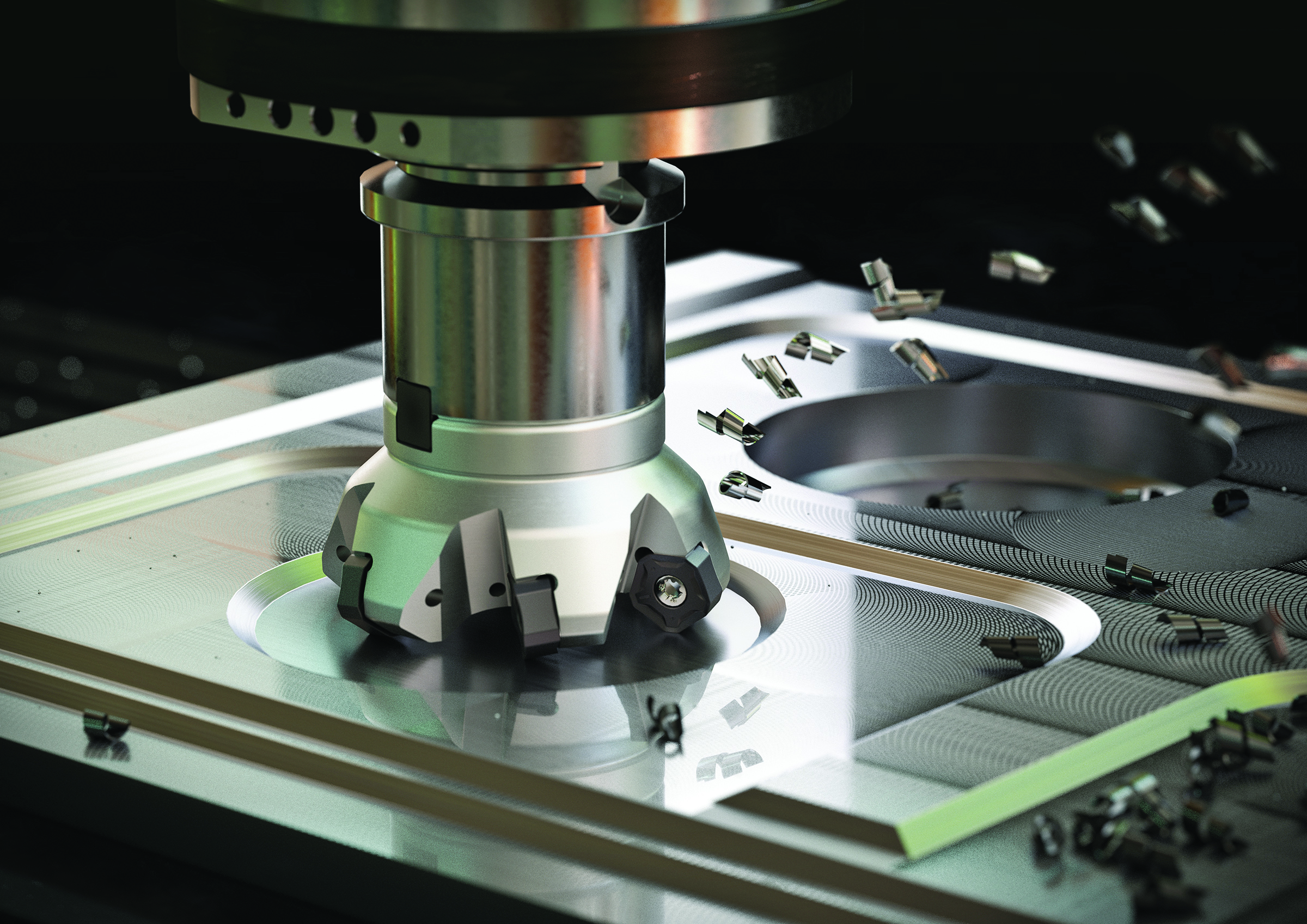

G750 5-axis Universal Machining Center

The G750's unique machine concept includes a horizontal spindle position that permits the longest possible Z-travel path and optimum chip fall. The arrangement of the three linear axes offers maximum stability by minimizing the distance between the guides and the machining point (TCP). The G750's tunnel concept allows the largest possible component to be swiveled and machined within the work area without collision – even with extremely long tools. Three linear and two rotary axes permit 5-sided machining, as well as 5-axis simultaneous interpolation, with a swivel range of 230 degrees in the A-axis and 360 degrees in the B-axis.