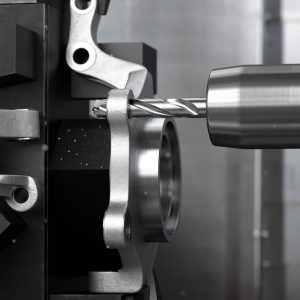

CoroDrill 400 and CoroDrill 430 Drills

Two new drills optimized for drilling aluminum automotive parts have been developed by Sandvik Coromant. Suitable for the machining of components in medium-to-large volumes, CoroDrill 400 and CoroDrill 430 deliver high throughput and low costs, as well as extended tool life and enhanced process security.

-300x200.jpg)