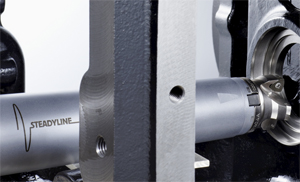

Machine Technology: No-hands tool changing

When CNC milling machines were conceived some in the metalworking industry asked why a computer couldn't also manage tool changes. That question was the impetus behind the development of the automatic toolchanger.