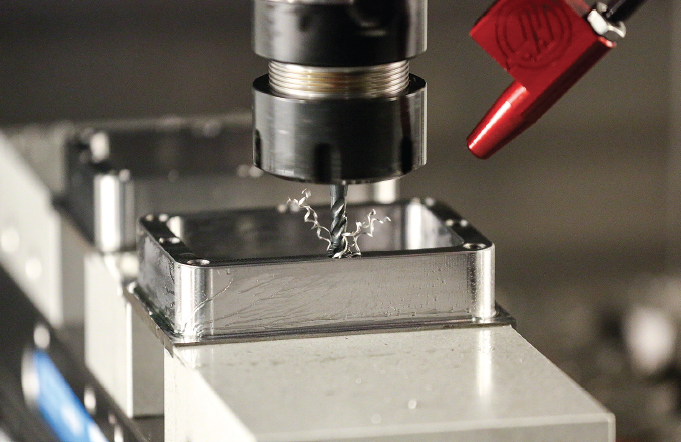

Full-Flow Filtration Technology

VOMAT says its full-flow filtration technology completely separates dirty oil from clean oil and allows for grinding with optimally cleaned cooling lubricants. VOMAT's filtration systems clean the oil so efficiently that it's useful life is much longer than if it were filtered with conventional filter systems still using paper filters or other expensive disposable filter media. A pleasant side effect is the low operating costs.