Products

•

February 26, 2019

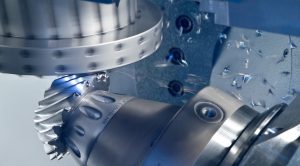

RP GOLD Water-Based Rust Preventive

Madison Chemical introduces RP GOLD, a versatile water-based rust preventive that provides long-term indoor storage protection for ferrous and copper alloys. Applied to previously cleaned parts by immersion, manual spray or recirculated spray methods, RP GOLD leaves a nearly invisible, dry-to-the-touch film that provides up to four weeks of protection (or longer when used at higher concentrations).

-300x166.jpg)