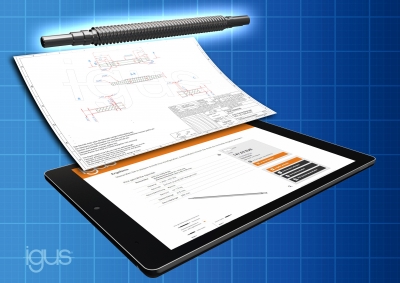

igus has developed a new lead screw configurator that will allow customers to quickly design their own lead screw and associated drawing without in-depth technical knowledge and CAD software. Designing a lead screw usually requires significant effort for the user, who is required to have technical drawing skills and access to a CAD program. Now, igus has developed a platform where anyone can use the largest lead screw shop in existence and design an individually manufactured and long-lasting part for their application.

The new online system from igus allows designers to configure a long-lasting lead screw in minutes.

Trapezoidal, high helix or metric thread lead screws in combination with nuts made of iglide high-performance polymers ensure lubrication-free adjustment for long lasting-and smooth-running applications. But designing the right drive solution has demanded significant effort and knowledge in technical drawing. From determining the right parameters up to machining the lead screw, and designing with a CAD program and checking for technical plausibility up to ordering, the process can take several hours or even days.

The new tool for igus directly checks the plausibility of the configuration. This way, anyone can become a designer without any CAD software. In three steps, the user can customize a lead screw, configure the machined end and directly generate a dimensional drawing. The designer can download the 3D model of the configuration and order the preconfigured lead screw or request a binding offer.

The three-step configuration process starts when the customer determines the type of lead screw. In addition to the classic trapezoidal thread and the metric thread, the user also has the option of choosing the dryspin high helix thread. This is a thread patented by igus, which ensures a higher efficiency through an optimized flank angle. After selecting the thread type, the user determines the thread direction, the material and the lead screw strength.

In the second step, the machined ends are configured. The configuration offers the user the opportunity to design the base body from outside inwards, and add 12 standard elements such as chamfer, champing surface or circlip to the machined end.

In the configuration process, the designer can download the current dimension drawing directly at any time. The price of the lead screw is displayed, so the user sees price adjustments during the configuration process.

In the final step, the customer receives a complete overview of the configuration. The designer can download the STEP file for further construction of the application, save the configuration as a link for follow-up orders, or share it with colleagues. With a simple click, the fully configured lead screw can be ordered online. The order is automatically transmitted to the igus factory, where processing starts within 30 minutes.

Contact Details

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.