MarWin Version 5.0

MarWin Version 5.0

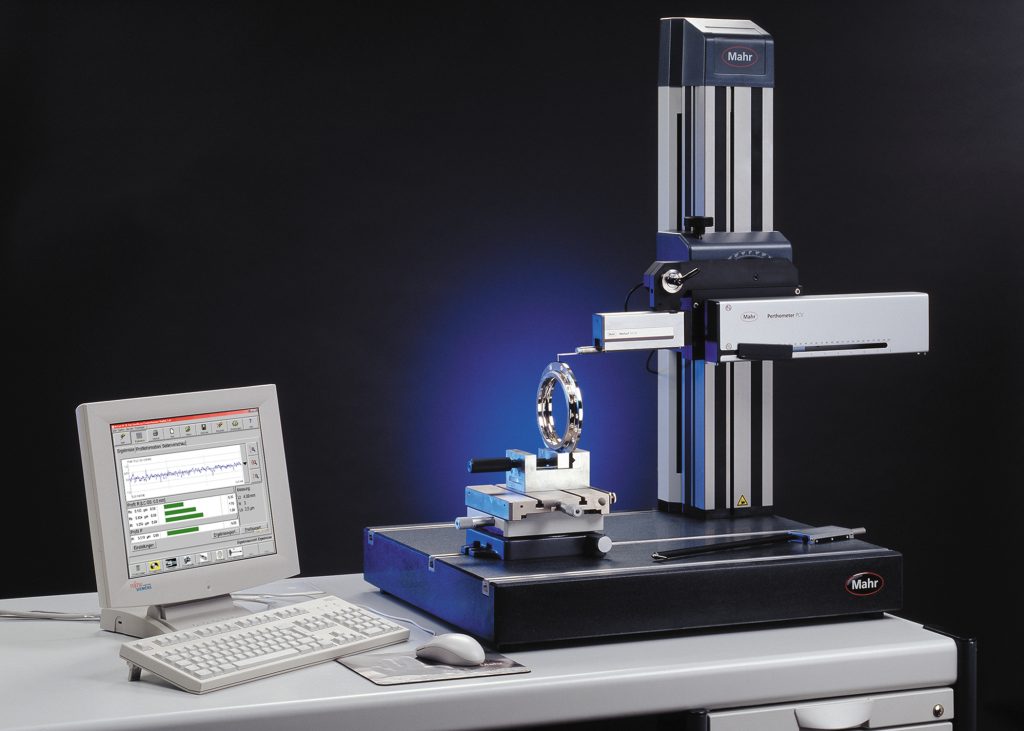

Mahr Federal Inc. has made the process of surface evaluation better, easier and faster with the release of the latest upgrade to its surface metrology software, MarWin Version 5.0.

Mahr Federal Inc. has made the process of surface evaluation better, easier and faster with the release of the latest upgrade to its surface metrology software, MarWin Version 5.0. The new upgrade includes: a patented new Tangential Elements function for evaluating transitional geometries such as radii, relief grooves, and chamfers; new ISO 16610 filters; and a host of new Assistants and Script integration functions that speed and facilitate the measurement and evaluation process.

"Tangential Elements is an entirely new function for contour evaluation software," said Pat Nugent, Vice President of Metrology for Mahr Federal, a member of the Mahr Group. "For the first time, users have a tool to evaluate those tricky transitional contour geometries like corner radii, chamfers and relief grooves. MarWin 5.0's patented process eliminates guessing by using tangential circles and lines to determine actual points of contact and best fit forms to provide uninterrupted line shape analysis between geometric elements."

New ISO 16610 Gaussian filters are also included in the MarWin 5.0 upgrade package, with ISO 16610-21 re-placing ISO 11562, and ISO 16610-31 replacing VDA 2008. However, operators still have the option of using the old filters if required by their applications.

"But the key development objective of MarWin 5.0 was to enhance usability," Nugent said. "The package includes a large collection of Assistants and other functions which really speed profile set-up and operation, and make the process of using the software much more flexible and efficient."

Improved general functions include automatic user log-on, zero setting of the probe using the Hz axis of the measuring stand, automatic zenith search, and automatic centering of the probe inside bores. A new Elements function allows you to make various elements used in profile construction either visible or not visible. This can dramatically clarify the screen view when creating or modifying a complex contour evaluation, for example.

Also, all hidden items can be made visible again with a single click, saving a great deal of editing time. A function called, "Contact line with defined angle," ensures there is only a single point of contact in edge detection, for example, or that reference lines are on the highest or lowest point. Defined angles can also be of help in searching for points of intersection with a fixed reference contact.

A Profile fit-in function allows the user to overlay a target profile with tolerance bands onto a measured profile. This can be very useful in wear measurements, or for the optical representation of tolerances, either scaled or non-scaled.

Finally, MarWin 5.0 is much more configurable than earlier versions. Mahr has made the integration of scripted or customized programs much easier, and has a large library of special modules available that can easily be integrated into MarWin 5.0. Scripts can be activated before measurement; after measurement but before analysis; or after analysis, when data can be especially configured to specific export criteria. Examples of scripted programs can include the addition of special filters, the calculation of special parameters, or the custom development of totally new measurement applications.