Noil Mist Collectors

Noil Mist Collectors

At a time when state and federal regulators may be moving toward tighter workplace safety requirements, ITA says it is assuring its customers that Coral Noil Mist Collectors far exceed minimum health and safety standards.

At a time when state and federal regulators may be moving toward tighter workplace safety requirements, ITA says it is assuring its customers that Coral Noil Mist Collectors far exceed minimum health and safety standards.

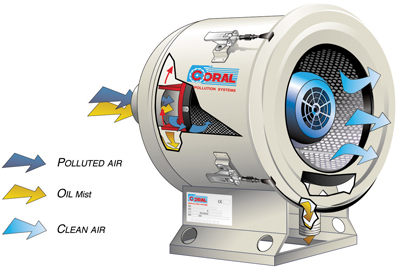

Noil Mist Collectors remove both water-soluble and oil-based mist used in machine tool operations through a three-stage filtration system. In the first stage an impeller converts the mist back into a liquid and recovers the coolant for recycling. Next, a dense cellulose filter cartridge removes finely aspirated particles. A third-stage high-efficiency polyester filter rated 99.9 percent at 2µm particle size removes remaining particles.

For shops that require an even greater degree of filtration, ITA offers customers a fourth stage Post Filter accessory that increases efficiency to 99.9 percent at 0.3µm particle size, and returns the clean air back into the work area.

"Airborne oil mist can land everywhere, on floors, machinery and employees," according to an ITA company spokesperson. "An effective mist collector reduces worker accidents caused by slips and falls from oil and dirt buildup on shop floors. And it improves air quality, minimizing health risks that metalworking fluids and machine mist can cause."

The high-speed impeller in Noil Mist Collectors is dynamically balanced, and the second and third stage filters do not rotate, assuring quiet and vibration-free operation, another workplace benefit. The compact design of the unit offers various mounting options: directly to the machinery, or on a floor stand, wall mount or ceiling suspension.

ITA's spokesperson points out that the same triple filtration system that provides safety benefits to workers also cuts down on a facility's production costs. By efficiently evacuating coolant mist and oil mist from the air, Noil Mist Collectors can then recycle them back to the machine tool, reducing the cost of coolants. A cleaner workplace environment also means less dirt and grime that can collect and eventually foul up machinery. Noil Mist Collector filters are made to deliver long-lasting performance, significantly reducing the frequency of filter maintenance and machine downtime. The polyester filter can even be washed and reused.