OMNIedge System

OMNIedge System

The OMNIedge network sets up automatically and sensors are simply installed on existing components for convenient and easy remote monitoring of operating conditions. Data is securely collected through a dedicated closed IoT networkfor analysis and to provide alerts. By monitoring and predicting damage and lubrication status, the OMNIedge prevents production delays caused by unexpected machine downtime and enables inventory management. n

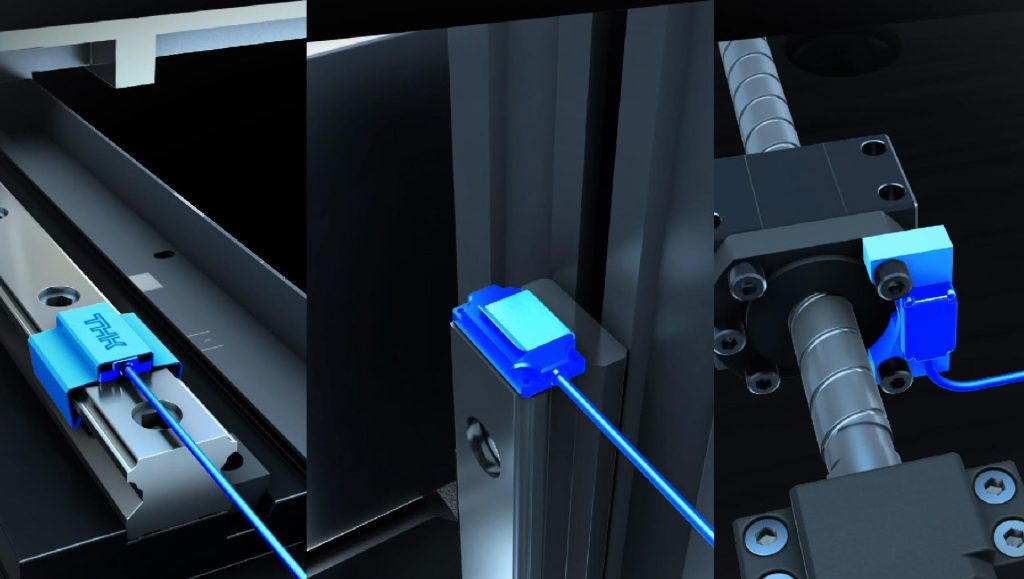

THK's innovative OMNIedge System enables predictive failure detection of linear motion components for improved productivity and reduced maintenance costs.

The OMNIedge network sets up automatically and sensors are simply installed on existing components for convenient and easy remote monitoring of operating conditions. Data is securely collected through a dedicated closed IoT networkfor analysis and to provide alerts. By monitoring and predicting damage and lubrication status, the OMNIedge prevents production delays caused by unexpected machine downtime and enables inventory management.

When the OMNIedge detects signs of component degradation based on threshold value, users can check inventory, order parts and schedule maintenance. This system enables the planning for and maintaining of a stable inventory of parts.

The THK sensing system operates with a Cisco edge computing router or smartphone and sends information through a NTT DOCOMO mobile network. Installation and operation of the system is simple, regardless of IoT expertise or experience.

Different sensor fasteners are available for mounting on different types of linear motion components. The OMNIedge system is designed for use in a variety of industries.

The OMNIedge System is currently not available for purchase in North America. THK plans to announce a release date in the upcoming months.