Square Dot 2-D Codes

Square Dot 2-D Codes

quare Dot, a patented high-resolution marking process from Columbia Marking Tools, permanently marks high-quality 2D/UID codes on a wide range of materials and costs less than laser marking.

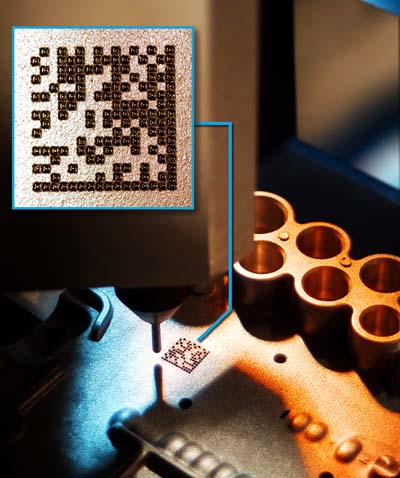

Square Dot, a patented high-resolution marking process from Columbia Marking Tools, permanently marks high-quality 2D/UID codes on a wide range of materials and costs less than laser marking. The process produces crisp, easily-readable codes on metals ranging from soft brass to carbide steel, and on hard-to-read cast surfaces. Square Dot codes can even be read after the metal is powder coated.

The Square Dot process (U.S. patent no 7,191,529) dot-scribes a matrix of small square cells with a diamond tip, creating the 2D/UID (Unique Identification) codes that manufacturers use for inventory management, quality control, security, and other purposes. Square Dot is more permanent than ink jetted codes, which can rub off in greasy conditions. It is reportedly more repeatable than dot peening, which is subject to stylus wear that can affect dot size consistency.

A 2D code has data encoded in its cells, which can be round, square or hexagonal, in light and dark areas. The dot-scribe process creates square, recessed cells with four raised ridges, producing reflections that help the machine reader define the matrix and read the data accurately. Square Dot cells are also deeper than those made by lasers, often with better contrast. These advantages are particularly important on irregular surfaces like castings, where dot-peened marks tend to blend into the background and surface imperfections may be mistakenly read as dots. Dot-scribed codes on castings, on the other hand, are clear and easy to read. Square Dot codes on aluminum automotive castings are routinely read with portable readers.

The Square Dot process is available from Columbia Marking Tools, using its versatile I-Mark system. The I-Mark IMC (Custom) Series does "Silent Scribe" and/or dot peen marking at marking speeds of five characters per second (with a stepper drive), or 10 characters per second (with a high-speed servo motor drive). Four different marking windows are available.

The I-Mark IM-IS (Integrator) Series is a "Silent Scribe' system that marks up to five characters per second and offers a large or medium marking window. Both series feature an advanced, compact controller, a long-life marking head and I-Mark 2D software, loaded onto the machine or an industrial PC.