Version 4.0

Version 4.0

Tebis America has announced the launch of its newest version 4.0 software.

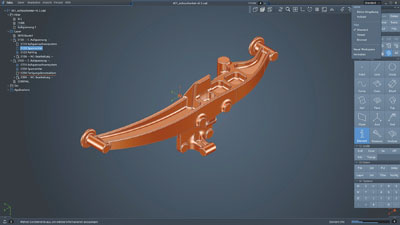

Tebis America has announced the launch of its newest version 4.0 software. The new release features a new visual design, intuitive access to the functions through self-explanatory icons and more feedback for the operator all without sacrificing tried and proven features.

"Our goal was to offer our customers a new user interface that provides excellent possibilities for interaction and is highly functional, as well as easy to work with. We're confident that we have succeeded," said David Klotz, CEO and President of Tebis America.

The user interface features color blending of modern colors as well as an updated typography that characterize the interface's appearance. The familiar Tebis blue will continue to be used in the future to highlight the selected functions. The dark color scheme used for the display is designed to optimize daily work on the monitor, be easy on the eyes, and facilitate individuals' work, thanks to improved contrasts.

The status bar has been considerably reduced to provide maximized space for graphics, while the dialog design has been revised and adapted to align with verified knowledge and experience regarding ergonomics.

With the new interface, the menus on the function panel can be shown or hidden, allowing users to individually configure the work area. A very important feature is that freely designed work environments can be saved and managed. The program specifies work environments that are targeted for certain applications.

In addition, users can configure their workstations to meet their needs and use the configuration again at any time. For example, they can keep frequently used CAD modules open in the work space for manufacturing design and switch to their work environment with preferred CAM modules for NC programming. Work environments can also be imported and exported for exchange with other Tebis workstations.

The new interface provides users with considerably more feedback than the previous version. During off-screen calculation Tebis allows up to six NC calculations to be initiated in multiple open CAD files. Thanks to the progress indicator covering multiple parts, programmers now have an overview of the status of the processes in the files. Any errors that occur during the calculations are communicated immediately to the user, also across multiple files.