ZeroAct Workpiece Positioning System

ZeroAct Workpiece Positioning System

With an ultralow profile of 40 mm and extremely flat design, ZeroAct is ideal for any zero-point application especially those where the z-axis travel of the spindle is critical. The ZeroAct features rapid open and closing of the modules and simultaneous actuation with one simple twist of the wrist generating 15kN clamp force. Easily actuate workpieces onto a table or adapter with a low stack-up of 38.1 mm greatly increasing the z-axis travel.

SMW Autoblok, a world leader in the design and manufacture of rotational chucks, stationary workholding, tooling and engineered solutions for the machine tool industry, introduces the connectable ZeroAct workpiece positioning system ideal for manual and electric zero-point clamping used in a variety of machining applications including milling, inspection, and finishing operations.

With an ultralow profile of 40 mm and extremely flat design, ZeroAct is ideal for any zero-point application especially those where the z-axis travel of the spindle is critical. The ZeroAct features rapid open and closing of the modules and simultaneous actuation with one simple twist of the wrist generating 15kN clamp force. Easily actuate workpieces onto a table or adapter with a low stack-up of 38.1 mm greatly increasing the z-axis travel.

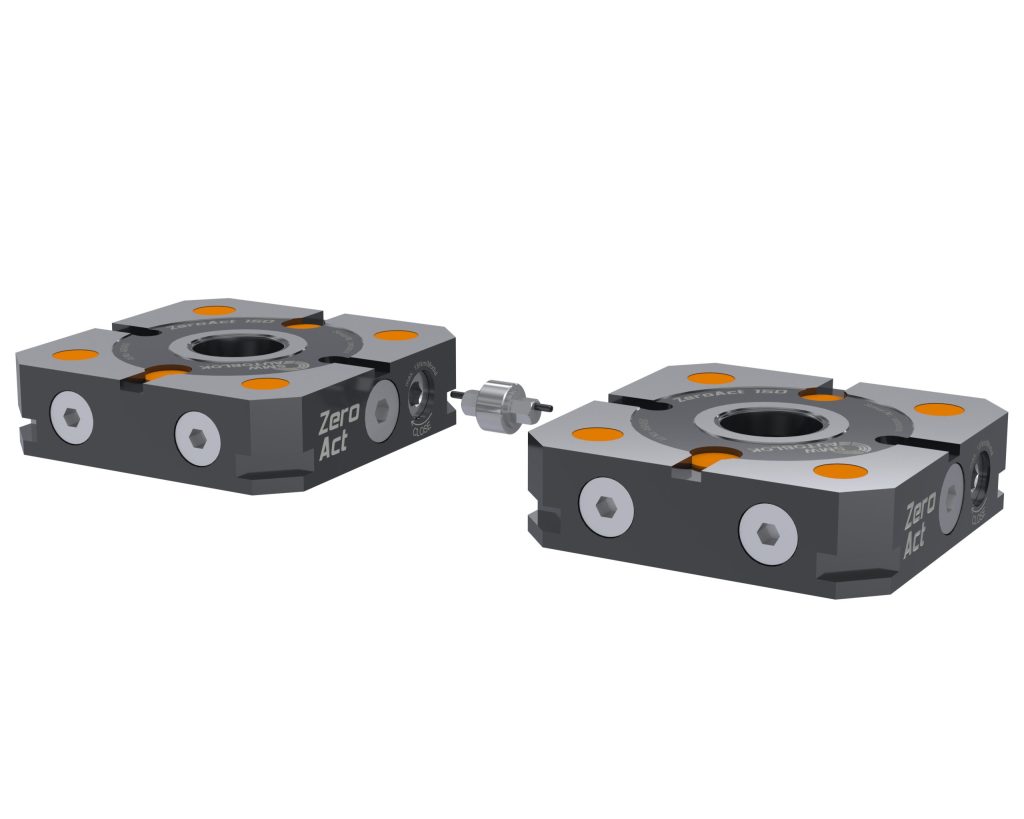

The modular ZeroAct system, with a compact size of 150 x 150 mm, offers the ability to easily attach up to three clamping modules in a row with a connecting pin that is available in sizes from 5 mm to 105 mm. By actuating the first unit, all three units clamp simultaneously therefore it is not required to lock each unit individually into position like others on the market. This benefit adds tremendous flexibility to machine operations, saves time and increases operator safety.

The ZeroAct is also available in an electric e-motion version, unique to the industry, to fully automate the manufacturing processes. Using 24V power supply that operates with a built-in electro-motor, this system offers great flexibility to machining processes. Switch between a manual and electric ZeroAct version for fully automating load and unload processes. Pull down pins are fully interchangeable with the manually operated ZeroAct and other APS/WPS zero-point systems.

All modules are proofline® sealed protected against corrosion and feature a built-in air cleaning function to ensure that the clamping system's support surface remains clean and free of chips during changeover or automation, greatly reducing maintenance and production time, and provide a repeat accuracy of <0.005 mm.

ZeroPoint is part of the comprehensive lineup of stationary workholding systems that include the manual and pneumatic WPS/APS clamping modules, fully customized and self-centering vises that fully integrate with automation and pallet systems, and SinterGrip® clamping inserts for ultra-low clamping depth and no pre-marking of parts. Systems provide high repeatability, maximum holding forces, and up to a 90 percent reduction is setup time.