Aerospace: Taking flight

Aerospace: Taking flight

Machining aerospace materials can be difficult, but tools and techniques are available to help.

Mission-critical aerospace components, such as engine and landing gear parts, turbines and blisks, must be made from materials that can withstand extreme temperature and stress. Those workpiece materials include heat-resistant superalloys and titanium alloys, whose composition and properties make them effective for demanding applications but also create challenges when machining them.

One requirement when machining superalloys and titanium is adequately pulling heat from the cutting zone, said Bill Durow, manager of global engineering for aerospace at Sandvik Coromant Co. in Mebane, North Carolina.

High-pressure coolant helps achieve that need because just applying a stream of coolant or flooding the zone with coolant is insufficient. Creating a parallel hydrolaminar flow with high-speed, high-pressure coolant also can assist with chip formation, said Brent Godfrey, machine integration product specialist at Sandvik Coromant.

"When the coolant nozzle is positioned correctly on the cutting tool," he said, "you can get the flow of coolant to act almost like a power wedge to curl the chip and help to mechanically break the chip in some materials. In materials like titanium, you can effectively break chips with high-pressure coolant, which is a good problem-solver on those materials."

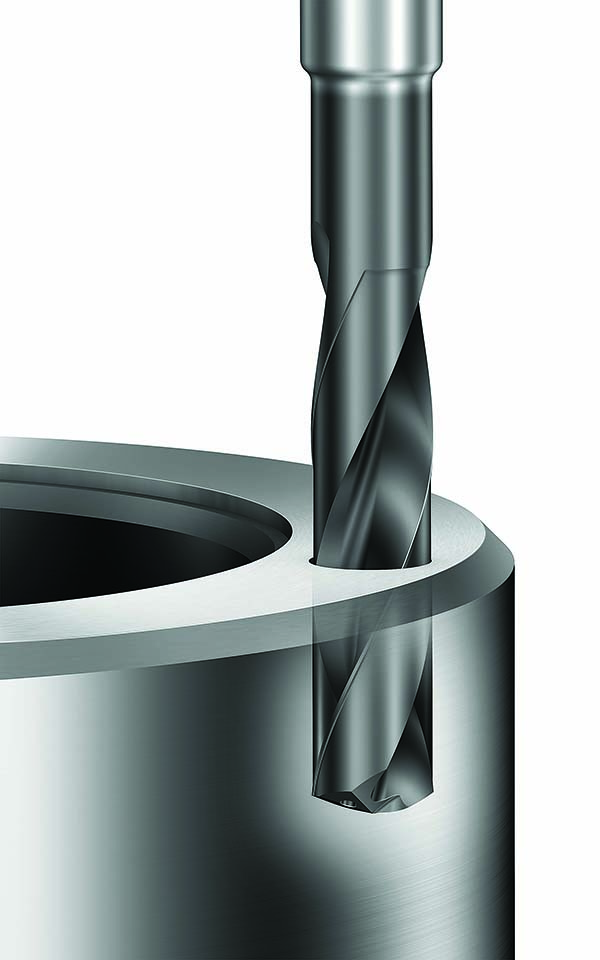

Machining aerospace materials can be difficult, but tools and techniques are available to help. Image courtesy of Sandvik Coromant

The minimum pressure on a standard high-pressure pump on many machine tools is about 69 bar (1,000 psi), Godfrey said, but pumps are available, such as on some vertical lathes, that go to 172 to 207 bar (2,500 to 3,000 psi).

The tool manufacturer reports that when it developed the first version of the Jetbreak high-pressure coolant system several decades ago, the Coromant Capto modular quick-change tooling system was the basis for that development and was designed with an internal coolant supply for pressures up to 138 bar (2,000 psi). Coromant Capto is a machine tool interface with a tapered polygon design that transmits torque.

Godfrey explained that Capto's self-centering coupling proves beneficial when machining aerospace materials.

"You just mount it into the tooling block and align the polygon to the other polygon that's in the tooling block," he said, "and the clamping unit and cutting edge is on center right away."

Durow added that the high level of repeatability for the modular quick-change system is essential for efficiently machining aerospace parts.

"Just taking the tool out, for instance, is an easy plug-in place for customers," he said, "especially when they deal with highly critical, highly valuable components."

Another major benefit of the modular system is that it provides a significant amount of pull force on the cutting tool, Godfrey said, noting that a Capto tool has a ground contact face and the polygon to provide two methods of contact for the coupling.

"It translates to very high rigidity, very high strength, very good bending stiffness of the cutting tool," he said.

Cutting tool geometries, including a positive cutting geometry and a comparatively open chipbreaker on indexable inserts, play a substantial role when machining exotic metals for aerospace parts.

"We have geometries specific for aerospace materials with special chipbreakers on them that are also designed to handle the high-pressure coolant," Godfrey said.

In addition, Durow said the toolmaker designs the insert top geometry expressly for aerospace materials.

"It has to be free cutting, but it also has to be strong enough to not break when it starts cutting the material," he said. "You need a good balance."

Material Movement

The introduction of different workpiece materials adds to the challenge of machining aerospace parts. For example, Durow said although they are not new materials, more parts for the hot section of aircraft are being made from single-crystal nickel-base superalloys, which provide enhanced microstructure thermal stability and improved mechanical properties.

Besides being difficult to machine, many aerospace materials, especially for spacecraft applications, are proprietary alloys that cannot be purchased from a local supplier to test tools and run trials, he said. Even the forging and casting companies that produce the materials are restricted from selling them to entities that lack certain contract agreements. Instead, Sandvik Coromant must develop partnerships with the aerospace part manufacturers to obtain the metals.

"Today," Durow said, "there's a lot of R&D going into these materials, so we're seeing more optimized solutions."

An illustration shows a CoroDrill 860 tool drilling a hole in an aerospace valve. Image courtesy of Sandvik Coromant

In addition to workpiece materials, he said cutting tool materials other than carbide are being used more to machine aerospace parts. Ceramic and polycrystalline diamond inserts can extend tool life, boost productivity or both. For example, while carbide inserts typically can run at a cutting speed of 45.7 m/min. (150 sfm) or less when machining heat-resistant superalloys, ceramic inserts can run from 213.4 to even 304.8 m/min. (700 to 1,000 sfm).

How a cutting tool is applied also influences tool life and productivity. For instance, Godfrey recommends against burying a cutter when machining nickel-base superalloys.

"We like to take a light and fast approach," he said. "The more you bury your cutter into a cut, (it) creates more of what we call a heat propagation area — the area where heat could build up."

"We've been preaching about lightning-fast, dynamic toolpaths, trochoidal machining, adaptive machining, light radial cuts and sweeping across the part instead of burying a cutter," Durow concurred.

However, changing a machining process for an aerospace component can be difficult because of industry regulations.

"Any part that's going to be dynamic, that's essentially moving, is typically considered critical," Godfrey said. "And unless they're going to do a lot of paperwork and a lot of cutups and trials, they don't want to change anything."

He said some processes and tooling for components were certified decades ago and aerospace part manufacturers still are not allowed to change anything, even though cutting tool technology has improved significantly.

"Ever since I started with the company, it's been a problem with these critical components," said Godfrey, who has been with the toolmaker for 24 years.

However, he said change is happening, albeit slowly, as manufacturers cannot keep up with the demand for airplane engines and other components and want to increase production.

"Times are changing," Godfrey said, "so it's good."

For more information about Sandvik Coromant, call 800-726-3845 or visit www.sandvik.coromant.com.