Coolant bucket brigade be gone

Coolant bucket brigade be gone

Automated coolant delivery system enables unattended machining

Using buckets, barrels and hoses to manually replenish coolant in machine tools doesn't cut it in this tight labor market or when a parts manufacturer wants to perform lights-out machining. That was the case for Precision Tool Technologies Inc., said Jim Goerges, president of the Brainerd, Minnesota, company.

"Like most companies, we were part of that 5-gal. (19-liter) bucket brigade," he said. "It was always a pain in the butt."

Goerges started PTT in 1993 with four products and now has about 6,000. The company does some job shop work but focuses primarily on the prescription eyewear industry.

"We don't make lenses or frames," he said. "We help the wholesale optical laboratories edge the lens to insert the lens into the frame and to put the prescription into the eyeglass lenses."

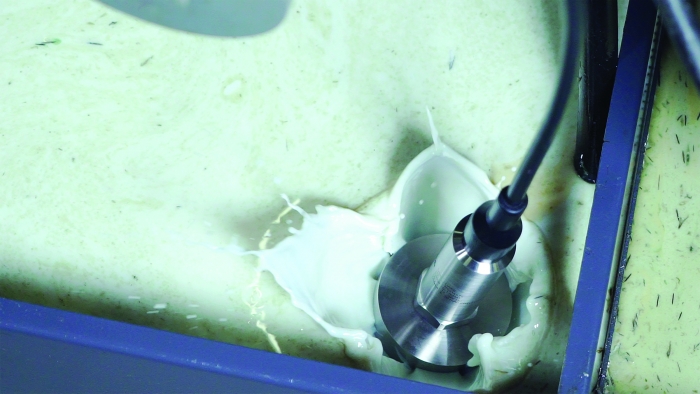

The FullShop automated coolant delivery system monitors coolant usage at a machine tool sump and automatically replenishes coolant before it runs low. Image courtesy of Precision Tool Technologies

That manual approach, Goerges said, meant that coolant wasn't replenished on a timely basis. Or workers would forget to do it, and a machine would run out of coolant, smoke, break tools and potentially crash. He also reasoned that his qualified labor was distracted from more important tasks when tending to coolant replenishment.

An additional problem was overfilling a machine with coolant.

"That happened all the time," Goerges said, "where you bring coolant to the machine, you forget how much was in there or the sight glass wasn't working because there was too much sediment in the tanks, and — lo and behold — you flood the machine."

When the company decided to acquire machines that could produce parts in one setup or two at the most, automation was required for unattended machining because PTT didn't want to add workers for the second and third shifts, he said. He calls unattended production "168 manufacturing" due to 168 equaling seven days a week times 24 hours a day.

Goerges tried with no luck to purchase a shopwide system that automatically would deliver mixed coolant with unique top-off concentrations. It seemed that there was no commercially available option, so he built one. The system needed to monitor all the machine sumps and accurately provide customized coolant percentages and de-foamers to machines.

"I didn't appreciate at the time how difficult it really was," he said. "How do you create this thing so it is predictable, accurate and repeatable?"

Goerges began by bringing a hose with a pressurized spigot to a machine.

"The machinist just needs to turn it on and turn it off," he said. "It sounds simple — problem fixed. But the machinists are multitasking, get interrupted and flood the floor. That didn't work."

Another concept was similar to an air gun in which a lever activated coolant flow and releasing the lever stopped the flow.

The system consists of a centralized pumping station, a controller, distribution manifolds and a sensor that drops into a machine tool sump to monitor the coolant level and temperature. Image courtesy of Precision Tool Technologies

"Problem solved, right?" Goerges said. "No, they put a rubber band around it because their thumb or hand hurt when they pulled the lever. So that wasn't a good way."

Adding to the challenge was the coolant foaming that occurred, especially when PTT performed high-speed machining at spindle speeds up to 80,000 rpm. He explained that excessive foam can shut down a machine or deplete it of coolant by causing a leak.

Starting nearly seven years ago, PTT engineered an operation that uses a state-of-the-art control system with motor-commanded pumps and flow meters, Goerges said. The system consists of a centralized pumping station, a controller, distribution manifolds and a sensor that drops into a machine tool sump to monitor the coolant level and temperature. PTT's in-house system is connected to 14 machines. However, the modular system is scalable up to 120 machines and can deliver as much as 21,804 L (5,760 gal.) of coolant a day.

He ran the initial beta unit for 4.5 years to vet the process. The goal was to run about 50,000 hours around the clock without realizing any failures, such as mechanical or electrical ones.

With its smart sensors, the system is Industry 4.0-compatible, he said.

"I can take a glance of the reports that come off this coolant system," Goerges said, "and in 10 to 15 seconds I can access how productive we were for the last night, last week or last two weeks."

In addition, human-machine interface visualization easily allows employees to see the bigger picture of what CNC machines are producing.

After making sure the system offered the required longevity, PTT decided to market the product to other manufacturers as the FullShop automated coolant delivery system. The company recently installed a system at a nearby location of another manufacturer, and prospects regularly visit these facilities to see the equipment operate, Goerges said.

He said PTT's product development for the prescription eyewear industry has enabled the company to have the mentality of an OEM.

"We are now an OEM for automated coolant delivery with this machine," Goerges said. "I know we are truly helping other shops with their profitability with this equipment and welcome people to reach out to review the ROI, which has proved to be very real."

For more information about the FullShop automated coolant delivery system from Precision Tool Technologies, view a video presentation at www.ctemag.com by scanning the QR code on your smartphone or entering this URL on your web browser: cteplus.delivr.com/28eqh