Cranking out power

Cranking out power

Eagle Machine Inc., in Abbotsford, B.C., frequently takes on challenging jobs, such as modifying a diving bell for deep-sea submarine rescues or designing and machining a set of solid aluminum wheels for an 800-mph land speed car based on an F-104 jet aircraft. Owner Steve Green said, "People come to us with the craziest things because other people tell them, 'the only place you can go is Eagle Machine.' "

All images courtesy of Pamela J. Tallman

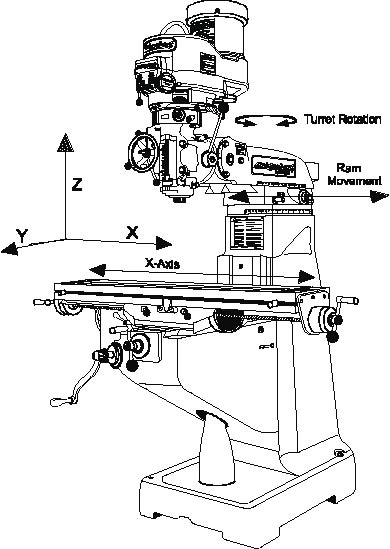

Three axes of movement and ram movement on a Bridgeport milling machine.

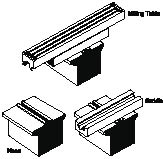

The knee casting (lower left), the saddle and knee joined by their dovetails (lower right) and the knee, saddle and milling table together (top).

Eagle Machine Inc., in Abbotsford, B.C., frequently takes on challenging jobs, such as modifying a diving bell for deep-sea submarine rescues or designing and machining a set of solid aluminum wheels for an 800-mph land speed car based on an F-104 jet aircraft. Owner Steve Green said, "People come to us with the craziest things because other people tell them, 'the only place you can go is Eagle Machine.' "

One customer needed a durable crankshaft for a 1,000-hp drag racing motorcycle engine. As a result, Eagle redesigned the engine and now produces it as the "Nitro V45." Based on a 45° V-Twin Harley-Davidson engine, the normally aspirated (nonsupercharged) motor displaces up to 200 cu. in., burns nitromethane fuel and can send a bike through the quarter mile in about 6 seconds, reaching a top speed of 235 mph.

The engine's block and heads are aluminum, but the crankshaft needs to be made of tougher material. Nitromethane carries its own oxygen and boosts power—and thereby stress on engine components—by a factor of 10. "You are hitting the crank with a big sledge hammer when you pour in nitromethane," Green said. "The crankshaft is the heart of the engine."

Accordingly, Eagle Machine determined that the best crankshaft material is EN30B steel alloy from Corus Group in the U.K. Green said the alloy is similar to 4340 steel but has more than 4 percent nickel content, compared to 4340's 2 percent or less. The alloy's high nickel content lets the crankshaft endure considerable flexing without cracking, but the increased toughness makes the steel more difficult to machine.

The shop acquires the alloy, in 23- to 25-HRC annealed condition, from distributor Encore Metals as 20 '-long, 8⅞ "-dia. bars in minimum shipments of 20,000 lbs. "We make 25 crankshafts at a time and 20,000 lbs. will make four batches," Green said.

The bar is sawed into 9 " lengths and chucked on a Daewoo Puma 300L CNC lathe, where half of the part is rough turned from a maximum OD of 8⅝ " down to a 2.776 " main bearing journal diameter. For rough turning, Eagle Machine uses a Sandvik Coromant grade-4015 CNMG 433 PR insert, applied at 300 sfm, a 0.150 " DOC and a 0.018-ipr feed rate. The part is then flipped for similar operations on the other end. Roughing leaves 0.030 " excess stock on the part for finish grinding after heat treatment.

After rough turning, the crankshaft is moved to a Haas CNC mill where the shop employs ballnose endmills to machine lightening pockets into half of the face of each end of the crankshaft.

Next, the shop rough mills the part's crankpin on a Takumi Seiki V10 AH vertical machining center fitted with a 4th- axis rotary table. The finished diameter of the crankpin, on which the pistons' connecting rods ride, is 2.375 ". To hold the part in the mill, "we have a fixture on the rotary table that we chuck onto one journal, and we stick a tailstock into the other journal to give it rigidity," said CNC Supervisor Dave Krol. A 50mm-dia., square-corner Iscar shell mill, tooled with five Iscar grade-950 inserts, then cuts a space in the middle of the crankshaft, creating two flywheels and the crankpin. The milling cutter is mounted on a 4 "-long extension made of tungsten to provide rigidity and dampen vibration.

Krol said the milling inserts run dry and "really hot." They're applied at a 0.100 " DOC and a 100-ipm feed rate. To machine the crankpin, "we bring the leading edge of the cutter in line with the center axis of the part diameter, and as the rotary table turns we move the Z-axis up and down to compensate for the throw of the crankpin," he said. Because the cutter isn't directly on center, the crankpin has a convex contour. The rough-milled crankpin has ¼ " of excess material, which is removed on a manual lathe. On the same machine, the inner sides of the flywheels are faced smooth.

Back on the Takumi VMC, Eagle Machine rough drills nine through-holes in each flywheel (opposite the lightened areas) to accommodate tungsten counterweights that balance the mass of the pistons and rods on the offset crankpin. The 1 "-dia., 11⁄8 "-long plugs weigh 5⁄8 lb. each. Tungsten is 2.5 times heavier than steel, and each crankshaft contains about $400 worth of the heavy metal.

The crankshaft is sent to Cascade Metallurgical, Kent, Wash., where it is hardened in a vacuum furnace to 42 to 43 HRC. It is quenched in high-pressure nitrogen gas, which produces less distortion than oil quenching, Green said.

The crankshafts are returned to Eagle where they are semifinish turned. "The sizes are tight and a cutting edge will only maybe last a couple of parts," Krol said. "It seems that every time you get your size set on the CNC lathe, your insert goes. Speeds run about half of what we were turning it before heat treat. Our feeds are fine, around 0.005 to 0.006 ipr. We have to maintain a good surface finish. At this point, we are shooting for a 32µin. Ra finish for the journals, but the flywheels don't really matter."

Next, holes for the tungsten plugs are finish-bored on the Takumi mill. Krol said the plugs themselves are ground to a tolerance of -0.000 "/+0.0005 ", and "we maintain 0.001 " of interference tolerance for the holes." Final machining involves manually drilling and boring pinion holes for the cam gear.

After quality assurance examination, the crankshaft goes to Lopez Crank Shaft, Santa Fe Springs, Calif., which grinds the two main bearing journals and the crank pin. The shop holds ±0.0001 " on diameters, ±0.0005 " on stroke length and produces a 5 to 8 µin. Ra finish. Green said Lopez has "never screwed up a crankshaft," such as by burning the radiuses, a common error that can lead to microcracking.

The crankshaft is shipped to Accurate Ion Technologies, South Gate, Calif., for an ion-nitriding surface hardening process set at 700° F to avoid softening the part's core hardness.

When the crankshaft returns to Eagle Machine, the tungsten plugs are pressed in and it receives a final surface treatment called Harperizing. Green said his shop has the only Harperizing machine in western Canada; it consists of a 5 '-dia., 2 "-thick steel wheel with two rubber lined tubs at its periphery. Parts are finished with a silicon-carbide media and a water-based lubricant at a force of as much as 25 Gs.

Green said his shop's $4,000 crankshafts last at least twice as long as the competition, completing perhaps 250 to 300 quarter-mile runs before replacement. "It took us a year to develop the process for this part because nobody in the racing crank business is going to tell you anything," he said. CTE

For more information about Eagle Machine Inc., call (866) 852-1277 or visit www.eaglemachine.ca.

Courtesy of Eagle Machine

Eagle Machine manufactures this 85⁄8 "-dia., 9 "-long crankshaft for a 1,000-hp motorcycle engine from EN30B steel alloy. At the left end is a 9310 alloy cam drive gear hobbed by the shop, and on the right end is a 4 "-wide black-anodized 7075 aluminum toothed pulley that drives a Kevlar-reinforced toothed belt to transfer power to the motorcycle gearbox.