Emag modernizes maintenance

Emag modernizes maintenance

The German machine tool manufacturer is working on a more automated version of its wear analysis system to put customers in complete control.

A German machine tool manufacturer is working on a more automated version of its wear analysis system to put customers in complete control of the process.

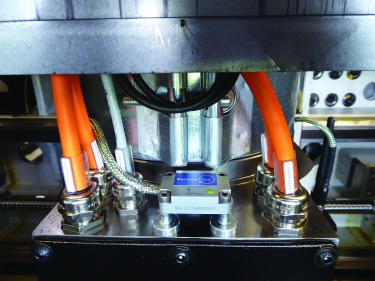

The current version of the system, developed by Emag GmbH & Co. KG, Salach, Germany, features a removable vibration sensor attached to a machine spindle. Conducted by a service technician, the process of assessing wear starts with a dry run of the machine that includes movement along every axis, as well as spindle rotation. During the dry run, the sensor measures vibration and sends the data via cable to a wireless device that transmits the data to the technician's computer.

Then the technician compares the measured data with the expected results. The more that the measured and expected results differ, the more wear that there is in the machine, explained Peter Strohm, Emag's global service project manager. By examining the data, he said, an experienced technician can spot trouble with a certain axis or axes.

Emag's vibration sensor attaches to a machine's spindle housing. Image courtesy of Emag

Emag calls this form of the system the mobile version because it requires a technician to come to the customer's shop with the sensor, which he or she attaches to the machine and then removes and takes away after the testing cycle. As the company sees it, however, this is the system's main downside because it means customers can't use the system themselves.

Soon, therefore, Emag hopes to replace the mobile version with a system that features a machine learning algorithm capable of processing sensor data to determine which machine components are likely to fail due to excessive wear. In addition, the mobile sensor will be replaced by a fixed sensor in every machine. This sensor will send data to a computer via cable rather than wirelessly because a cable connection is more reliable, Strohm said.

With the machine learning algorithm evaluating the sensor data, Emag aims to eventually cut technician visits from the process.

"As we get better at this and as the algorithm works better," Strohm said, "the process can be fully automated and the customer can have it whenever he wants by just pressing a button."

The new technology was co-developed by data analysis company anacision GmbH, Karlsruhe, Germany. Emag has acquired a minority stake in anacision, which develops machine learning systems.

"We think machine learning will become more and more important for drawing the right conclusions from a lot of machine data," Strohm said.

Emag also has high hopes for a new service app designed to make it easier for a customer's maintenance staff to get in touch with Emag's service department. When the app scans a QR code on an Emag machine, it shows the machine's serial number and the right contact information for the customer's country and machine type. The customer then can choose to contact Emag specialists by phone or email. For problems that are difficult to describe in words, Emag offers customers the option of initiating a live video chat, during which they can show a video of their problem to a service specialist.

Strohm said the app also helps Emag get the information it needs when a customer contacts the company for service.

"Some customers find it difficult to give us the right machine serial number," he said. "Even though it is written on a plate on the backside of the machine, customers often call and say something like, 'I have a problem with my blue machine in the third building.' But we need the serial number because each machine we build is more or less unique and we have to know the exact configuration in order to give him the right advice for his problem."