Enduring attachments

Enduring attachments

Tapping attachments date back to the early 20th century—and they've endured for good reason.n

Think of the oldest piece of machinery your shop uses regularly. Is it 20 years old? Maybe 30 years? Now, consider why it still sees action—probably not just because it still works, but also because the mechanical design is similar enough to modern equivalents that it can perform jobs in a shop today.

That's a big part of why drill head and tapping equipment manufacturer Rockford-Ettco Procunier still gets repair tickets for tapping attachments, or heads, that date back to its founders' first entries into the field a century ago.

"The technology is very old," explained Larry Bull, president of the company's Procunier arm in Lakeland, Fla. "We actually have a couple of Procunier tapping heads that date back as far as 1919. We still repair tapping attachments that date back to before World War II, which we know because they are made of cast iron rather than aluminum."

Which all begs the questions: What exactly is a tapping attachment, and why have they been part of the machining industry for so long?

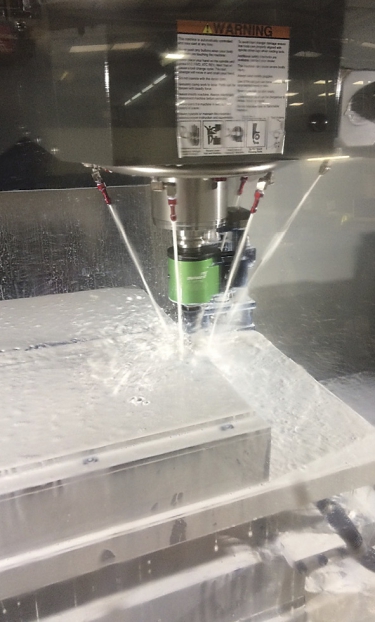

Tapmatic says its RCT50 self-reversing tapping attachment allows for faster cycle times and less wear on both tap and spindle. Image courtesy of Tapmatic.

Synchronous Fix

First, it's good to understand the different methods of tapping. "Rigid tapping" involves inserting a tap directly into the toolholder of a lathe or mill. Rigid tapping can be done by a master machinist who knows the proper speeds and feeds and how to reverse out of the hole without breaking the tap or the threads. On a CNC machine, the spindle drives the tap into the hole, stops at the bottom and reverses, extracting the tap from the hole at the same speed.

"There's a lot to be said for the simplicity of rigid tapping," said Bill Cox, Procunier product engineer. "We have a VMC that we regularly use for rigid tapping because, especially if you only need to tap a couple of holes, it's just a simple tool change."

The downside, he continued, is that the spindle must come to a complete stop and reverse while still in the hole, which puts the tap in suboptimal cutting conditions and increases wear on the spindle.

If rigid tapping is not the right method, there are two other general methods to choose from, according to Bob Warfield, CEO of Aptos, Calif.-based CNC training resource and software builder CNCCookbook Inc. There is "floating tapping," which involves the use of tension-compression or radial-parallel tapholders, and there are self-reversing tapping attachments.

"It all boils down to accurately synchronizing the motion of the tap to the geometry of the thread," Warfield said. "If you spin that tap at a certain rpm, it had better advance into the hole at the rate the thread's pitch requires."

The Tapmatic ASR and RSR self-reversing tapping attachments' more

compact design is suited for modern CNC lathes. Image courtesy of Tapmatic.

Machines for rigid tapping are accurate enough that they don't need a tapping holder or attachment to achieve that synchronicity, he explained, though holders and attachments can help increase tool life and decrease cycle times. In fact, simple tapping heads are effectively ancient technology at this point, having been originally developed for manual machines, such as the drill press and the venerable Bridgeport knee mill, with the resulting process commonly referred to as "power tapping."

A tension-compression tapholder is spring-loaded, he continued, allowing it to compensate for slight axial movements the tap might experience as it enters or exits the hole. "You can push or pull the tap in and out a little bit as it's working, and because of the flexion inherent to the design, the holder will account for any 'slop' that comes about," he said. Radial-parallel tapholders, as the name implies, offer radial rather than axial float.

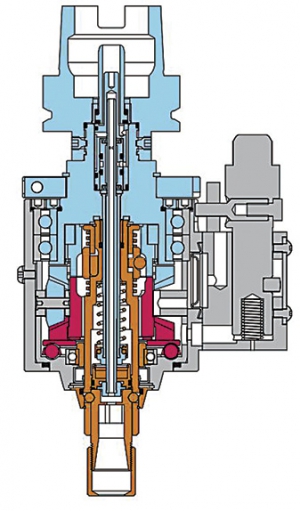

Tapping heads feature an internal gearbox and are self-reversing. They allow a machine spindle to continuously rotate in one direction. The tapping attachment rotates and feeds the tap into the hole. Once the desired thread depth is reached, the attachment's gearing reverses direction and the tap is retracted from the hole without the machine spindle stopping or reversing direction.

Attachment Advantages

Tapmatic Corp., Post Falls, Idaho, has manufactured tapping attachments for the metalworking industry since it opened shop in 1952, said the company's president, Mark Johnson. Tapmatic specializes in self-reversing attachments for conventional milling machines, CNC machining centers and CNC lathes with driven tooling.

"The biggest advantage to a self-reversing tapping attachment is cycle time," Johnson said. "For example, if you are tapping an M8 [-sized hole] at 2,500 rpm, a self-reversing attachment will save you 35 to 40 percent on cycle time, compared to tapping the same hole at the same speed by reversing the machine."

Those numbers are not guesswork, either. Tapmatic has tested its method against the alternatives, and the productivity gains are impressive.

In one series of tests, the company rigid-tapped 80 M8 × 1.25 holes in 6061 aluminum on a CNC lathe running at 2,500 rpm; the results were that 33 holes per minute were tapped. Next, the company rigid-tapped 80 more holes, but at a speed of 4,000 rpm. Theoretically, significantly increasing the speed should significantly reduce cycle time. But at the higher speed, just 35 holes per minute were tapped—less than one-fifth of a second difference per hole vs. 2,500 rpm.

Tapmatic tapping attachments include a patented reversing ball drive, which allows

for an immediate changeover into reverse once the desired thread depth is reached. Image courtesy of Tapmatic.

"It's difficult for the machine to accelerate and decelerate efficiently," Johnson explained. "If you are tapping a hole and only going 12 or 13 threads deep, the machine has to go from full speed to zero in that short number of revolutions, then reaccelerate to come back out of the hole."

In the final phase of the testing, a set of 80 holes were tapped using a new Tapmatic ASR50 self-reversing head running at 2,500 rpm. By running the spindle at a consistent speed and using the internal gearing to reverse the tap, Tapmatic was able to thread 52 holes per minute, cutting nearly three-quarters of a second per hole.

"Not only do you get tremendous time savings, but it's easier on your tap, your machine tool and your electric bill," Johnson said. "Stopping and restarting the spindle over and over uses nearly three times the electricity compared to running it at a consistent speed, so between that and putting less wear and tear on the tap and the machine spindle, a self-reversing tapping attachment brings some major advantages, provided you're tapping enough same-sized holes to justify the setup time."

Custom Solutions

The science behind tapping attachments hasn't changed substantially since William Procunier began manufacturing positive-drive reversing tappers in 1912, or George Emrick was granted a patent for the first self-reversing tapping head in 1925. What has changed, however, is the industry as a whole—and tapping heads along with it.

"We've gone from these simple tapping chucks to lead-screw tappers to gear-driven tapping attachments, and are now into custom machinery designed for a specific part," said Procunier's Bull. "But it's all based on the same principles."

As new workpiece materials and new advancements in CNC technology are developed, new approaches must be taken. Tapmatic, for its part, maintains a database of more than 2,000 tapping head installations it has completed on various machine tools, allowing the company to quickly and easily submit a proposal drawing for the complete assembly—the tool, as well as the stop block to keep the housing from rotating—and deliver everything ready to go, Johnson said.

"The antirotation feature [for tapping attachments] is similar to what you'd use on an angle head or a spindle speeder, and the programming is more complicated as a result of the added parameters, compared to rigid tapping," he said. "But once you've made the program, it's very simple to run."