Exploring mother machines

Exploring mother machines

Kip Hanson delves into what it takes to make the machines that make machine parts.

Machine tool construction is a contentious subject. Nowhere is this more evident than with "mother machines," highly accurate machine tools used to make parts for other machine tools. For a builder to say that it uses someone else's machine tools to build its own machines would be like Ford Motor Co. saying its corporate fleet is filled with BMWs and Acuras. This is why most builders prefer to drink their own machine tool Kool-Aid whenever possible. It gives them a chance to test and further refine their wares. Equally important, it sends a clear if unstated message to potential customers: "If our lathes and mills are accurate enough to machine our own parts, they're certainly accurate enough for yours."

75,000 Hours

Robb Hudson, CEO of Mitsui Seiki (U.S.A.) Inc., Franklin Lakes, New Jersey, suggested that the term is becoming watered down as an increasing number of builders proclaim themselves members of a once-elite club.

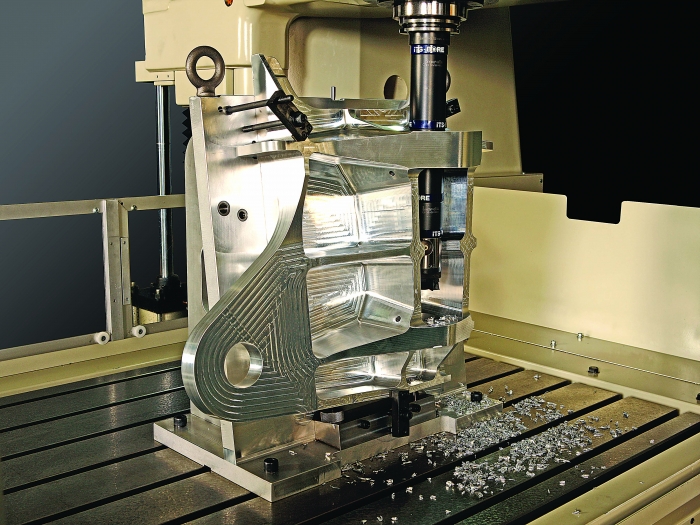

Mother machines are used widely in the aerospace industry to achieve extreme accuracy when producing critical components. Image courtesy of Mitsui Seiki (U.S.A.)

"In order to produce a mother machine, you must have a level of precision that's not easily attainable, and the ability to deliver that precision means painstaking preparation of the various components that make up the machine tool," he said. "A significant portion of our domestic market business comes from the machine tool industry."

To Hudson, mother machine means volumetric accuracies better than 20μm over "large areas." It means submicron positioning accuracy and repeatability without CNC compensation. Perhaps most importantly, it means that the machine will continue to perform at these levels for 75,000 hours, even under heavy cutting loads.

"It's one thing to achieve that accuracy when the machine is new, but how about 15 years from now, after thousands of hours cutting hardened materials, nickel alloys and titanium?" Hudson said. "The harmonics and forces generated when machining these materials causes deterioration of various machine components, which in turn leads to ballscrew wear, spindle failure and general loss of accuracy. It's easy to make claims of mother machine accuracy, but the real proof comes later, after the machine has seen years of production work."

Mother status aside, a prime market for these machine tools is the aerospace industry, he said, which calls for extreme accuracy when producing parts such as titanium aircraft structures, landing gear and engine components. Mitsui Seiki is also enjoying increased demand from the military and defense sector, particularly with satellite imaging applications.

Golden State Mothers

DMG Mori USA Inc., Hoffman Estates, Illinois, is another builder using its own equipment for machine tool production. CMX Product Manager Daniel Amendola listed four components critical to constructing the "machines that make the machines."

- Accuracy: Precision is essential for a mother machine to produce high-quality components for machine tools.

- Capability: The machine must be able to accommodate very large, complex castings while still providing the required accuracy.

- Flexibility: The machine must have enough power to handle a variety of materials and multiple axes to cut compound angles.

- Quality: The quality of each component and control of each process from the very beginning must be unmatched.

"When we set out to manufacture our mother machines, we rely on our powerful standard machine models to get the job done right the first time and for years afterward," he said. "It is a testament to this quality-focused approach that other machine tool builders utilize our equipment to create components for their own products."

The Mazak Versatech V-140N 5-axis double-column machining center is for machining large workpieces thanks to its spindle head that can position to the vertical and horizontal positions and any angle in between. Image courtesy of Mazak

Amendola noted DMG Mori's mother machines are built to stringent specifications and have the same quality and accuracy requirements as the company's standard production machines, "utilizing many of the same components as our high-production models to simplify service and support.

"We use six Japanese- and German-made DMG Mori milling machines with automation in our Davis, California, facility to produce many of the major components for our NHX horizontal machining centers and CMX vertical machining centers," he added. "This is also the approach taken by our other manufacturing facilities worldwide. The advantage of using our own machines in our factories is that we can then utilize the feedback from our manufacturing engineers to improve and iterate our designs, ultimately providing better products to our customers."

Off the Shelf

With the advent of more capable, accurate machine tools, manufacturing them has become simpler. The number of operations needed to complete any given component is less than it once was, and performing fewer operations generally enhances accuracy. This is the premise behind Mazak Corp.'s "Done in One" philosophy, which is demonstrated at its Florence, Kentucky, factory.

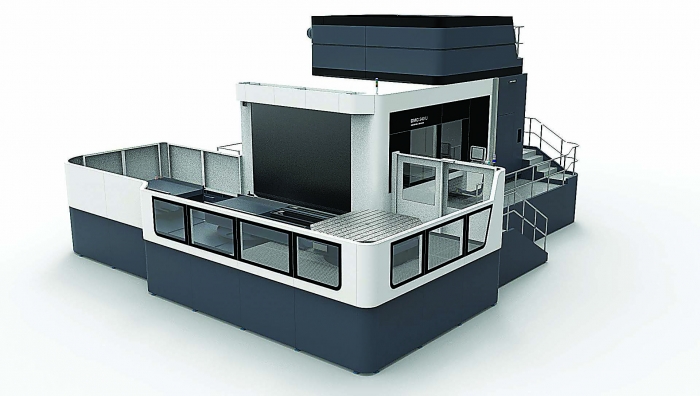

DMG Mori's 340 U 5-axis portal-style machining center boasts a table capacity of 22,000 lbs., sufficient for many machine tool components. Image courtesy of DMG Mori USA

"We use all our own machine tools to produce our machine tools," said Ben Schawe, vice president of manufacturing. "There's really nothing special about these machines, meaning that they are all standard products for us. For example, we machine the base of our machines on a Mazak V140 bridge mill equipped with a 5-axis head. This allows us to machine every contour on that part in one setup, which greatly reduces the accuracy loss associated with multiple setups." That said, this is the same machine tool technology the company sells to all its vendors, distributors and customers, Schawe noted.

Schawe agreed that a highly accurate machine tool is needed for the micron-chasing that Mazak and other builders do, but there's much more to the mother machine story than the equipment. "We tell our customers that, in order to maintain the stated accuracies, the machine has to be placed on an appropriate foundation," he said. "There's also the environment. You can't expect to make accurate parts when the shop is 50° F one day and 90° F the next. That's why all our facilities are air-conditioned, something we recommend to anyone attempting to maintain close tolerances."

Open Possibilities

"Okuma has a philosophy of designing, engineering and building everything ourselves," said Wade Anderson, product specialist, sales manager and tech centers manager for Okuma America Corp., Charlotte, North Carolina. "Not only do we build our own machines, but we also design and manufacture all of the electronics. When you look inside the electrical cabinet, you're not going to see third-party company names on anything. That's an Okuma servodrive. That's an Okuma encoder. That's an Okuma servomotor. And just as important, that's an Okuma control."

Assembling a double-column machining center at one of Okuma's Dream Sites. Image courtesy of Okuma America

Anderson said this tradition dates back to the company's founding in 1898. Like the others interviewed for this article, the machine tool of choice for machining the large iron bases common to virtually all lathes and machining centers is a double-column gantry mill.

"We build on average 44 of those machines each month in our Kani (Japan) facility, many of which go to other machine tool builders," Anderson said.

If you're wondering about the actual construction of the machine tools discussed here—for example, whether they use box or linear guide ways or whether the spindles and ballscrews are chilled—be aware that each builder has its own opinion. While Mitsui Seiki presents arguments for hand-scraped conventional ways, Mazak stands behind roller guide ways. Okuma has a mix of both, and most of DMG Mori's machines use linear ways, box ways or even a combination of the two on the same machine. All offer some form of thermal control on critical components.

"I'm originally from Missouri," Anderson said, "and there's an old saying I grew up with that's appropriate here. When someone asks me which machine tool construction is better, my reply is simple: 'Who's the prettiest girl at the dance?' The answer depends on who's looking. So when I look at boxed way versus linear way or any of the other available machine tool technologies, the choice of which one to use is largely process-specific. Fighter jets and passenger aircraft have their own merits, and selecting which one is best for the job at hand depends on what you're trying to accomplish. Do you need to be moving in fast, dynamic, high-G maneuvers, or are you carrying a large payload in one direction? The same can be said for machine tools."

Making Machinery

Coldwater Machine Co. produces machined parts, tools and automated machinery. Notable projects include a friction welding cell that attaches nuts to automobile body panels, turnkey systems for making washing machine components and maintenance tools for gas turbine repair. Its 132,500-sq.-ft. facility in Coldwater, Ohio, boasts more than 40 machine tools, among them double-column bridge mills, dual-pallet horizontal machining centers, large-format boring mills and a 5-axis multitask machine.

Despite these extensive capabilities, however, Coldwater found itself looking for ways to reduce the processing time on its components while improving quality. "We serve multiple markets, but most of our customers are in the automotive, aerospace or energy sector," said Dan Barry, vice president of sales and marketing. "One of these is a Japanese engine manufacturer for which we were building multispindle machining components that require positional tolerances of around 0.0002". That's why we bought the Mitsui."

Coldwater Machine's 30-year-old Mitsui Seiki jig boring machine still achieves a like-new level of accuracy. Image courtesy of Coldwater Machine

At 30 years old, the Mitsui Seiki SCN-II jig boring machine is clearly no spring chicken, but Manufacturing Manager Steve Zoda said it still holds "nanolevel" accuracies. "Aside from the older FANUC control, I think it's as good as the day it was shipped out of their factory. We really lucked out finding this machine."

As their name implies, jig borers machine holes to extreme positional and diametrical tolerances. Prior to purchasing the Mitsui Seiki machine, Coldwater employees were forced to jump through extensive machining hoops to achieve the required accuracy on the engine boring machine they built. The jig borer changed all that.

"We were using the run-of-the-mill machine tools found in pretty much any job shop," Zoda said. "That meant a lot of in-process inspection. We'd rough out a component, bring it into inspection and stick it on a CMM, take those measurements back to the shop floor and make another cut, basically sneaking up on the final dimensions. It was a labor-intensive, error-prone process. The Mitsui has cut our processing time by at least 50 to 60 percent, and the parts come out right every time."

Barry agreed. "Now we can rough, semifinish, finish, and the part's done without having to do a bunch of in-process inspection," he said. "We've found that this particular machine is as accurate or maybe even a little more accurate than our CMM. It's this level of precision that has allowed us to become even more efficient than we once were. It's a beautiful machine."

For more information about Coldwater Machine Co., call 419-210-1646 or visit www.coldwatermachine.com.

—K. Hanson