Improving the Threading Process

Improving the Threading Process

Vargus GENius app helps company choose a threading tool.n

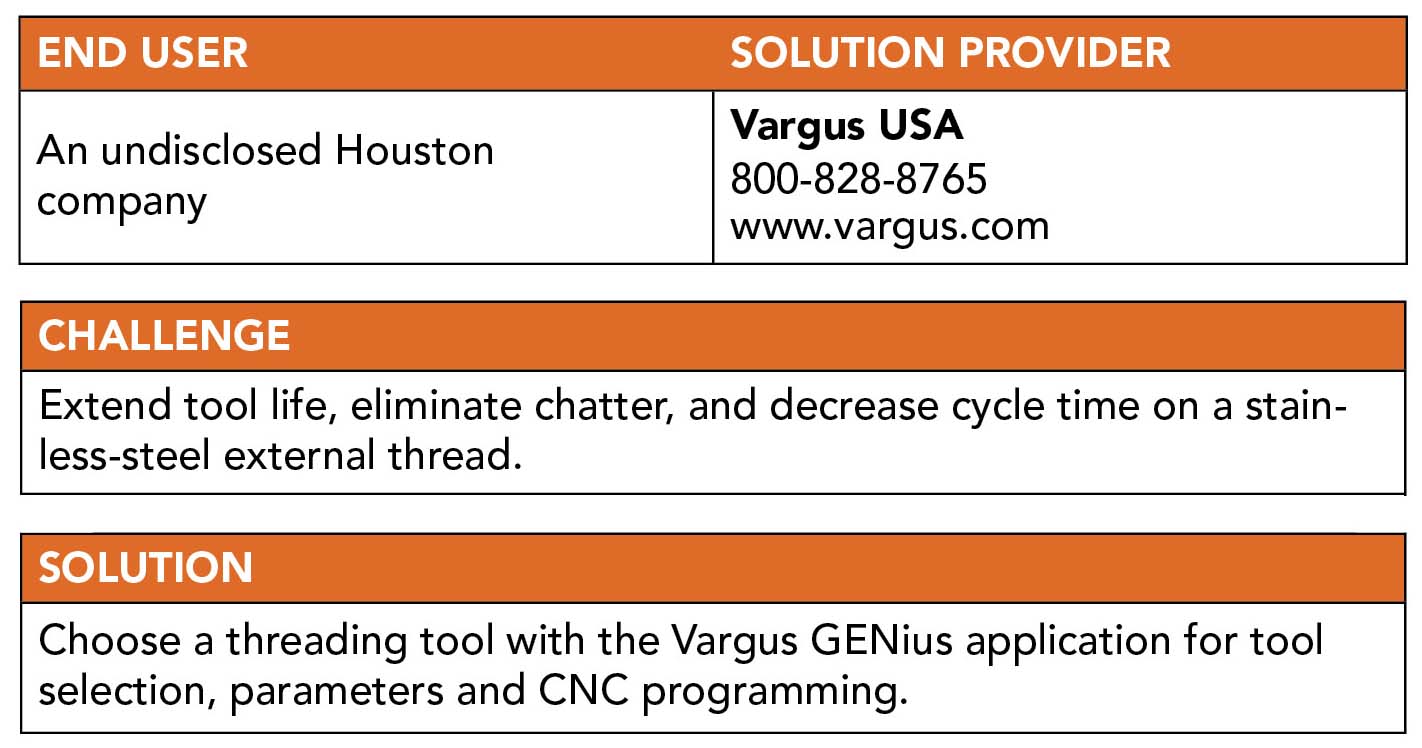

Whether it's cutting tool life, price, performance, or equipment obsolescence, job shops have a host of challenges they must overcome, said Tracy Hebert, Application Engineer for Janesville, Wisconsin-based Vargus USA. Hebert's territory covers Texas, Louisiana and Mississippi.

An undisclosed shop in Houston, for example, required assistance to improve tool life while eliminating an occasional chatter problem when threading a thin wall 316L stainless steel seamless tube, he said. The part had a 4.00" diameter with 8" pitch NPT threads and was produced on a Puma 400 CNC lathe with a Fanuc control. After producing five to six parts, the machinist had to index the insert to a fresh corner.

To help improve the process, Hebert said he showed the shop supervisor the Vargus GENius application for tool selection, parameters and CNC programming. (The Vargus GENius app can be found at Vargus.com or downloaded from the app store on any iPhone or Android smartphone.) Hebert walked the supervisor through the application process, initially indicating the part requirements: a right-hand thread externally threaded toward the chuck with an 8" pitch NPT, one start and a 4.00" nominal size. In addition, M13 was selected as the material class because 316L stainless falls under that classification.With this information, GENius offered 231 options, Hebert noted. The GENius can then be filtered down to the best tooling for the application. The machine requires a toolholder with a 1.25" square shank, which Hebert selected in the app filter. That information reduced the number of options to 26. The AL125-3 option was chosen, with the app indicating to use a YE3-1N anvil. Next, they selected the Vargus 3FSER8NPT-FST TiAlN-coated insert with a 3/8" inscribed circle, from the Vargus FS line of fully sintered inserts.

For infeed, the shop supervisor selected the radial infeed method, Hebert said. In addition, a higher threading speed was selected. "The end user was running at 468 SFM. For this insert and material, I chose to go with 520 SFM." Next, they selected 15 threading passes, he noted.

Upon completion, the GENius app provided a full thread turning summary for the application, including thread data, machining operation, parameters, pass details and ordering information for the tooling, toolholder and insert. End users can print the requested information or email it.

When testing the summary over two days, the Vargus FS insert threaded 16 parts per edge without any chatter, Hebert said.

"Also," he added, "we machined the thread five seconds faster. Multiply that by 2,000 parts and you have another big savings. The end user was very happy with the results."

In addition to a test report, Hebert said he provided a cost-savings report, which showed savings of more than $10,700. "This was a win-win for the end user. They achieved better performance, better tool life, quicker machining time and gained exceptional cost savings."

As a result, the customer, which has several U.S. locations, requested tests on additional machines and applications using various Vargus product lines, he added. The workpiece materials range from cast iron to Inconel alloys, with the parts having both internal and external threads.