Justifying custom cutting tools

Justifying custom cutting tools

When possible, manufacturers should avoid applying custom cutting tools because they typically cost more than standard catalog items and can be used only for a single purpose. In addition, it is difficult to substitute other tools in place of a special when it is out of stock, and lead times for new custom tools can be long.

When possible, manufacturers should avoid applying custom cutting tools because they typically cost more than standard catalog items and can be used only for a single purpose. In addition, it is difficult to substitute other tools in place of a special when it is out of stock, and lead times for new custom tools can be long.

However, when standard tools cannot produce the required part geometry, the custom tool costs less than a standard or the custom performs better than a standard, a custom tool can be justified. Cycle-time requirements can also justify combining multiple machining operations into one custom tool.

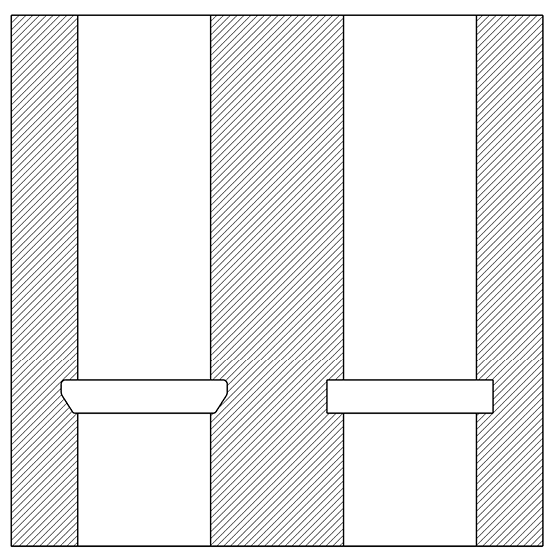

Figure 1. The left bore has a more complex ID groove that requires the use of a custom form tool, whereas the right bore has a straight-sided groove that a standard tool can make.

The power and flexibility of CAD and CAM software and CNC machine tools make machining complex shapes easy and affordable and reduce the need for custom cutters. The first CNC machine tools were developed to make complex aerospace components that could not have been economically produced otherwise.

NC machines use linear and circular interpolation between Cartesian coordinates to produce complex shapes with amazing accuracy. Unfortunately, interpolation does not work when a tool cannot access the area to be machined. Grooves with odd radii, for instance, often require specials. For straight-sided grooves, however, a standard grooving tool can be interpolated to achieve the desired dimensions (Figure 1). Special thread forms (threads are helical grooves) can also require specials.

As noted, a custom sometimes costs less than a standard. For example, I was tasked with reducing tool costs on a NC turning center that used 2.0 "-long, ⅜ "-dia. endmills with a 0.625 " flute length to mill flats on a round part. The milled flats were 0.010 " deep, so only the very end of the tool was used. To save ½ " of carbide per tool and the extra flute grinding expense, I specified a ⅜ " custom endmill that was 1.5 " long and had a 0.250 " flute length.

Many shops perform high-feed milling and high-speed machining and take advantage of chip thinning. These techniques produce toolpaths that have small DOCs and higher-than-normal feed rates. Because the chips produced are small and thin, the milling tool doesn't require deep flutes. And because feed rates are directly proportional to the number of flutes, more flutes means faster feeds and, therefore, shorter cycle times. Some toolmakers offer cutters specifically for HSM, but the selection is small and the tools are expensive, so a custom may be justified in these situations.

As I've urged in past columns, shops should take advantage of NC capabilities to minimize the number of tools stored in a machine's tool magazine. For example, use circular interpolation with an endmill to enlarge drilled holes rather than using multiple drills, or use an endmill to mill and counterbore instead of loading counterbores.

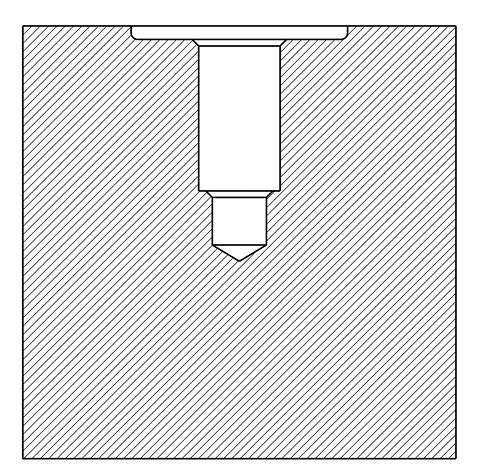

However, high-production shops often have cycle-time requirements that prevent this approach. Automotive manufacturers machine millions of parts each year and a cycle-time reduction of 1 second leads to significant savings. Therefore, a tool that produces multiple geometric features simultaneously often becomes a necessity. A job shop might create a complex hole using five tools for spot drilling, drilling, reaming, spotfacing and chamfering, whereas a custom combination tool eliminates the need for multiple operations (Figure 2).

Figure 2. These hole features, which are similar to ports in hydraulic components, could be produced by applying numerous standard tools, but if it's a high-volume parts application, a custom drill that creates the features in one operation is easy to justify.

Another time, I was tasked with reducing tool costs for a work cell and found that one custom milling tool had marginal performance and added a significant amount of cost to the part. Nonetheless, part geometry required a custom form tool because there was no way to produce the shape with a standard. The original special was a ¾ "-dia., 4-flute endmill with a single cutting end. Because the carbide substrate was about half the tool cost, I saved 35 percent by switching to a double-ended tool with a ⅝ " shank. Also, performance increased by altering the clearance angles on the tool and adding two flutes.

I default to standard tools when planning a new process but do not hesitate to use specials when appropriate. Be creative and ask toolmakers about their ideas for unique solutions. With effective design and planning, custom tools can boost efficiency and profitability. CTE

About the Author: Christopher Tate is senior advanced manufacturing engineering for Milwaukee Electric Tool Corp., Brookfield, Wis. He is based at the company's manufacturing plant in Jackson, Miss. He has 19 years of experience in the metalworking industry and holds a Master of Science and Bachelor of Science from Mississippi State University. E-mail: [email protected].