Living Large With 3D Printing

Living Large With 3D Printing

Ingersoll's MasterPrint 3D printer tackles extra-large parts seamlessly

Size matters, and the MasterPrint 3D printer with milling capabilities is living large. Built by Ingersoll Machine Tools Inc., Rockford, Illinois, the printer is part of a new line of additive manufacturing equipment that seamlessly programs, simulates, 3D-prints and mills extra-large composite parts in a single piece.

With the University of Maine, MasterPrint 3D-printed a hollow beam structure 7 m long × 1.6 m wide × 1.8 m tall (23'×5.2'×5.9') with over 2,155 kg (4,751 lbs.) of carbon fiber-reinforced acrylonitrile butadiene styrene, said Piergiorgio Assandri, business director of composites and additive at Ingersoll Machine Tools. The machine prints a wide array of materials in various orientations and finishes parts with five-axis milling. The company says part manufacturers can benefit by combining their traditional skills with MasterPrint's disruptive processes.

He said the platform can handle polymers and aluminum and has a working volume of 12 m × 4 m × 2.5 m (39.4'×13.1'×8.2'). The five-axis milling head runs at 25 kW (33.5 hp) and 18-rpm max spin using an HSK 63A toolholder. Designed for fast prototyping and making aerospace and naval molds, the printer can serve a wider market, namely companies needing wide and tall parts that are cost-effective, quick and reliable. MasterPrint uses a Siemens Sinumerik 840D sl CNC. Everything is fully automated, including changing cutting tools.

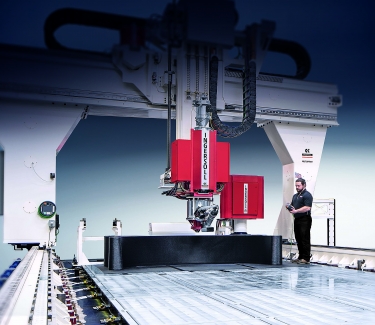

An employee works with the MasterPrint 3D printer and five-axis milling machine. Image courtesy of Ingersoll Machine Tools

Aerospace manufacturers have selected thermoplastics capable of enduring the autoclave process and used MasterPrint to make durable molds for production. Until recently, Assandri said, the molds were milled using Invar steel, an expensive nickel-iron alloy with minimal thermal expansion coefficient, which preserves mold geometry during the autoclave process that wings, fuselages and nacelles go through. The lead time for Invar molds was months. Once the molds were made, any refinements to them for the geometries of the related aerostructures added more time and expense. With MasterPrint, lead time is shortened to weeks, he said, and manufacturing costs are reduced by 90%.

"At pretty much the same time, the naval sector … saw the opportunity to print and mill — first their own molds and then their entire boats — with MasterPrint," he said. "Real boats, tens of meters long, (were) used as models to validate the hydrodynamics of their hulls before building them out of fiberglass."

In addition, Assandri said the automotive industry plans to use MasterPrint to print and mill electric vehicle chassis and truck cabins.

For more information about Ingersoll Machine Tools, call 815-987-6000 or visit www.ingersoll.com.