Machine monitoring goes remote

Machine monitoring goes remote

Machine monitoring can make shop operations more efficient, especially in a pandemic.

By Jim Romeo

Widely used for innumerable industrial applications, machine monitoring has many benefits for equipment operation. For machine and cutting tool operations, monitoring gives helpful data to make operations more efficient and supplies great utility to a machine shop during a pandemic.

"Machine monitoring nowadays entails remote monitoring," said Daniel Fernandes, senior product manager of bandsaws for Lenox Tools in East Longmeadow, Massachusetts. "Different platforms can aggregate data and information about machine tools in operation and provide owners and operators with trends and data to drive decisions. Such decisions include maintenance, downtime and other information."

He said machine monitoring can increase machine utilization and productivity.

"Both of these factors have a direct impact on a company's bottom line," Fernandes said. "Most companies are trying to get this type of technology into their plants, but there is a long way to go before this becomes mainstream. We are in the very early stages of adoption at this point."

Pandemic-Friendly

For many machine shops, COVID-19 has posed a challenge. Industrial hygiene emerged as a factor that promotes remote or automated operations when possible.

"The global pandemic has taken a toll on operations as facilities have increased precautions to ensure workers and facilities are safe from the virus," Fernandes said. "Automated operation is advantageous, but many operations on the shop floor need operators, and that will likely continue going forward. If technology gains can help limit the number of operators needed or how often they are needed, that will help."

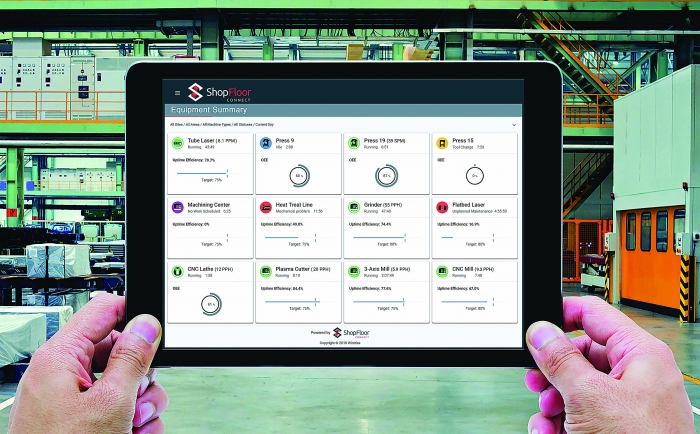

ShopFloorConnect tracks machine uptime and downtime, reasons for downtime, production rates and piece part counts when applicable. Image courtesy of Wintriss Controls Group

He said the pandemic has forced facilities to operate lean and ensure they have procedures in place for quick turnarounds of incoming orders.

"Automation will continue to gain traction," Fernandes said, "and COVID-19 will continue to push that initiative forward."

Jim Finnerty, product manager at Wintriss Controls Group LLC in Acton, Massachusetts, said a key to monitoring is consistency.

"Machine monitoring implementations that use a mix of dissimilar interfaces on machines often lack the ability to collect the same consistent set of data that is necessary for effective machine monitoring," he said. "When all machines are equipped with the same purpose-designed interfaces, the tag data, nomenclature, collection frequency and other factors are consistent, enabling accurate comparisons among machines. In other words, you won't be comparing apples to crab apples. Consistent machine interfaces also enable operators to move from machine to machine without having to learn a new method of data reporting and collection."

Finnerty said the pandemic has put machine monitoring in the spotlight as it is a means of being productive while minimizing contact and human intervention with machines.

"Whenever and wherever possible, companies are requiring all nonessential-to-production personnel to work from home," he said. "More than ever, managers and decision-makers are working remotely, and they require production data that is accurate, unbiased and — most of all — timely. This is impossible without a reliable machine monitoring system."

Finnerty said the need to maintain production in the wake of COVID-19 has minimized the traffic of contractors, subcontractors and other personnel who transit through machine shops or become close to operations.

ShopFloorConnect's machine interface is network-ready and factory-configured to drop right into an existing ShopFloorConnect installation and begin collecting data. Image courtesy of Wintriss Controls Group

"An underreported effect of COVID and the resulting lockdowns on industry has been that outside contractors, installers, trainers and support technicians are often prevented from making site visits," he said. "Software and hardware vendors have had to adapt by ensuring adequate remote support for their products and redesigning hardware interfaces so that they are more easily implemented by the end users. This is challenging given the wide variety of machines and controllers that need to be connected to the data network. Suppliers need to provide an interface that collects the necessary information from the machines without a complex integration with existing controllers."

Finnerty advocates a smarter means of data collection as a best practice in machine monitoring.

"Standardize on an easy-to-install interface that does not require modifications to existing machine controllers, collect production information in real time as automatically as possible with minimal manual operator input (or) entry, and place the data into a standard database like Microsoft SQL so that it can be shared with your other business systems," he said. "In addition, your data collection system should have the ability to automatically alert the appropriate personnel when a machine or process needs attention."

Finnerty believes that data collection can be strategic for remote machine monitoring.

"Companies that have implemented robust and reliable automatic data collection systems are better positioned in today's environment," he said. "Such businesses are now reaping the benefits of timely, accurate and unbiased information that helps them keep the machines running, the orders on time and the competition in the dust."

Paperless Workflow

Paul Van Metre, president of ProShop ERP in Bellingham, Washington, said machine monitoring could be valuable during COVID-19.

"Many shops already have their machines more than 6' (1.8 m) apart, which makes it easier to comply with those safety guidelines," he said. "But it is recommended that leads or other employees don't stand next to a machinist running a machine to check in with them to see how things are running. Machine monitoring can help with this by allowing anyone to remotely monitor the status of all machines without having to walk the floor asking machinists how their jobs are going and possibly creating a situation where exposure to an infected employee happens."

Van Metre said the pandemic has forced shops to consider the location, movement and proximity to others of all employees. The most severe effects have been to office spaces, where employees typically are in closer quarters than on a shop floor.

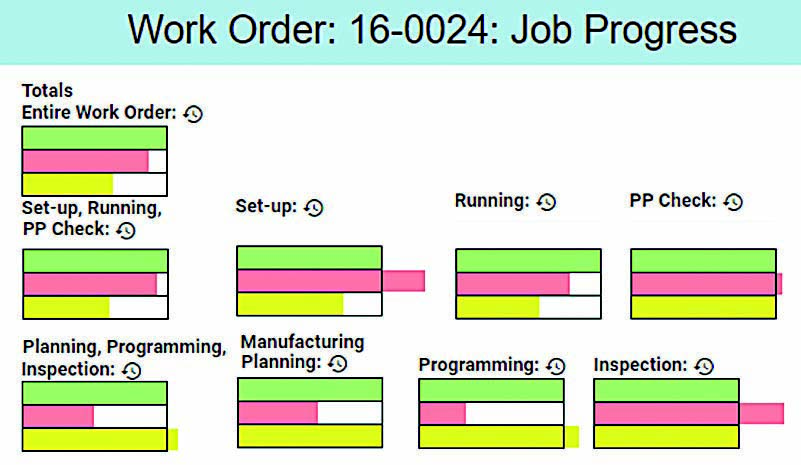

With robust machine monitoring, machining operations may be viewed simultaneously at a glance.

"The fewer employees who are in the facility, the safer people are and the less likely it is that a single employee who has COVID will infect many others," he said. "This is highly dependent on the business processes of the company and the logistics of how people know what work they have to do."

Van Metre said a paperless workflow can benefit both a shop floor and an office.

"In a paper-based workflow, employees are notified of work by the movement of paper travelers that arrive in their respective inbox, and then it is incumbent on them to read the information on the paper itself to know what to do," he said. "Clearly, a paper-based workflow is a significant impediment to effectively working from home, and processes would need to be significantly transformed for that to be an effective solution. We've had customers who have sent the majority of their office staff home for the past several months because their workflows are paperless and they don't need to be in the office to effectively do their jobs."

Part of the Solution

Van Metre said machine monitoring is not a cure-all.

"The root causes of machine downtime require deeper solutions to solve," he said. "Too many companies get the software, have it installed and hope that it helps them dramatically increase spindle utilization, which isn't always the case. First, the organization must be well trained on how to use the software. The configuration of the software must be well thought out and implemented. Things like downtime reasons must be configured and properly set up so that operators can correctly identify and report why machines are down. There are effective human systems to monitor those reasons and put in place effective solutions to solve the root causes of downtime. Also, there are many activities that employees engage in which are not at the machines and machine monitoring will not help with. Since labor is generally the largest expense of any shop, monitoring needs to be paired with an effective labor tracking system for all employee activities. Ideally, this system would go deeper than most ERP systems allow for."

Fernandes said a machine monitoring program must be easy to use and involve little operator input to function.

"The ability to have the program or product work on all machines within a facility is also needed," he said. "Of course, being able to have a dashboard that is easily accessible with data that matters is also key to success."