Machine Tool product review for March 2013

Machine Tool product review for March 2013

A collection of machine tool products compiled by the editors of Cutting Tool Engineering magazine.

United Grinding offers universal cylindrical grinder

United Grinding Technologies Inc.'s Studer favoritCNC universal cylindrical grinder is for processing medium-sized workpieces in individual and serial production. The machine offers a 25.6" grinding length, a 6.9" center height, a workpiece-weight capacity of 176 lbs. and accepts grinding wheels with maximum diameters of 20"×2.5"×8". The machine bed is made of solid Granitan S103 to enhance damping behavior and ensure a fine workpiece surface finish, according to the company. The V and flat guide ways for the cross slides are molded directly into the machine base and are finished with a nonabrasive Granitan S200 slide-way coating. The surface structure prevents the slides from hydroplaning and eliminates the stick-slip effect. The longitudinal and cross slides are manufactured from gray cast iron and have ground V and flat guide ways, with the distance between guide ways optimally suited to the machine's overall rigidity, according to the company. The slides are advanced by 40mm-dia. circulating ballscrews connected to a three-phase servomotor via torsion-resistant, bellow-type couplings. The turret wheelhead can be used for external and internal grinding. The turret can be equipped with an extra grinding wheel and internal grinding spindle for this purpose. The user can manually index the turret wheelhead in a Hirth gear within a swiveling range of -15°/ +195°. Options include in-process gaging, balancing systems, contact detection and length positioning.

United Grinding Technologies Inc.

www.grinding.com

Belt machines for continuous blasting

Rosler Metal Finishing USA LLC's RDGE series wire mesh belt machines are for continuous blasting treatment of flat and dimensional components. With four or eight high-power Hurricane blast turbines vertically or horizontally mounted around the housing, the machines can be used to treat complex parts, such as ones with pockets, intricate designs and difficult-to-reach areas, the company reports. A belt guiding system enables the lower turbines to blast only through one belt position to keep masking to a minimum. The wear-resistant wire mesh belt, with tension adjustment, reliably transports parts, according to the company.

Rosler Metal Finishing USA LLC

www.rosler.us

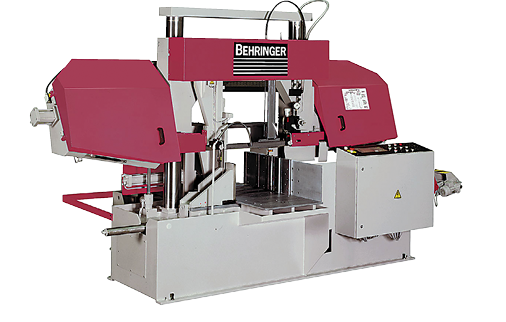

Automatic bandsaw cuts bars and pipes

Behringer Saws Inc.'s HBP-610A bandsaw is for cutting pipes and solid bars up to 24" in diameter. The cast iron saw frame has a dual-column design, which utilizes positive hydraulic down feed. The solid cast bow frame eliminates vibration and provides rigid support for blade tensioning, according to the company. The high-torque, frequency-controlled saw drive provides cutting speeds from 62 to 426 sq. ft./min. An automatic pressure sensing system monitors the down feed power and saw blade pressure. Cutting pressure data is analyzed and the system automatically makes blade pressure adjustments as needed to ensure an optimal balance between the feed rate and blade pressure.

Behringer Saws Inc.

www.behringersaws.com

Machining centers from Hyundai WIA

The L2100Y/SY CNC multitask turning centers from Hyundai WIA Machine Corp. have a wedge-type Y-axis and a BMT 65 (VDI 140) turret for milling and turning complex parts in a single setup. The 4,500-rpm synchronized 8" main spindle and 6" subspindle on S-configured machines enable turning of the front and back of cylindrical parts. The swing over the bed is 630mm, swing over the carriage is 300mm, maximum turning diameter is 335mm and maximum turning length is 468mm (455mm on SY). All axes are driven by double-nut ballscrews to eliminate thermal growth during machining, according to the company. All ballscrews are connected directly to the servo drive motors without gears or belts, eliminating backlash.

Hyundai WIA Machine Corp.

www.en.hyundai-wia.com

Heavy-duty lathe has small footprint

The Hi-TECH 450 horizontal turning center from Hwacheon Machinery America has a 500mm turning diameter and 1,350mm turning length. A spindle with integral motor offers a low speed of 800 rpm for high-torque turning and a maximum speed of 3,500 rpm. The rapid feed rate is 20 m/min. for the X-axis and 24 m/min. for the Z-axis. Turret indexing time to adjacent tools is 0.25 seconds, and turret capacity is 12 tools. The machine has an integrated 45° bed frame to minimize heat distortion and promote chip shedding and access to the work area, according to the company. The hand-scraped guide surface and bed design absorb vibration to enhance stability during hard turning. The geared transmission system is separate from the spindle motor to avoid the negative impact of transmission heat and vibration on the spindle. Six machine configurations are available, according to Hwacheon. A Y-axis is optional, which can be added to the MC/SMC type of the machine, reportedly reducing cycle times for multiple-function operations.

Hwacheon Machinery America

www.hwacheon.com