Metalworking product review for September 2013

Metalworking product review for September 2013

A collection of metalworking products for your review.

Fine-boring systems achieve closed-loop boring

The Romicron fine-boring systems from Kennametal Inc. allow users to dial-in close tolerances while a boring tool is mounted in the machine tool. They can produce finish bores with tolerances of a few microns in diameter and bore-to-bore variations of a few tenths of a micron, according to the company. Using cartridges or boring bars, Romicron tools can be adjusted in diameter with a dial ring in 2µm increments. To provide instant adjustment feedback, the system has a clicking mechanism so machine operators not only see the adjustment on the scale, but hear and feel it. The tools can run in spindles up to 20,000 rpm and with high-pressure coolant up to 120 bar (1,740 psi).

Kennametal Inc.; www.kennametal.com

New generation of tool presetters can be used in shops

Koma Precision Inc. offers the Hathor Six (pictured) and Sethy Six tool presetters from Elbo Controlli. The Hathor Six is the floor model and the Sethy Six is the bench model. The presetters have a measuring range of 600mm (23.62 "), fixed target function in micrometric registration of the X and Z axes, and a high-definition 15 " TTF touch screen. Manual control of the C-axis is optional. The units have a ground granite column and base, a spindle body assembled on spring roller cages and optical scales. The movement accuracy of the X and Z axes is guaranteed through the use of stable granite supporting surfaces, according to the company. The thermal inertia of granite allows a presetter to be placed in a shop environment.

Koma Precision Inc.; www.komaprecision.com

Semisynthetic coolant targeted to aerospace industry

Vasco 7000 metalworking fluid from Blaser Swisslube Inc. is a water-miscible, bio-based, semisynthetic emulsion formulated for high-speed milling of aerospace-grade titanium and nickel-base superalloys. The emulsions are sustainable and registered for use under the USDA BioPreferred Program. According to the company, the low-misting metalworking fluid, with enhanced washing action, does not require secondary amines or formaldehyde-releasing condensates to maintain long sump life. It is chlorine-free and reportedly provides high-cutting performance, increased productivity and long tool life when cutting exotic alloys.

Blaser Swisslube Inc.; www.blaser.com

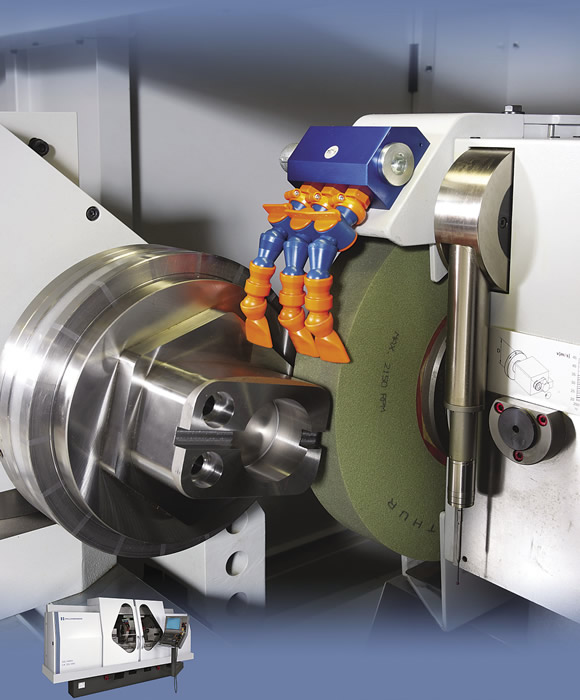

Cylindrical grinder has a direct-drive workhead for heavy parts

The Kellenberger Kel-Vari CNC universal cylindrical grinding machine from Hardinge Inc. has a robot and a rigid, direct-drive workhead for grinding heavy parts. A torque drive allows heavy parts to be quickly and precisely accelerated and braked without backlash during bidirectional movements for increased productivity, according to the company. Users can perform cylindrical, OD and ID, out-of-round, thread and jig grinding in one setup. The direct-drive workhead has an infinitely variable spindle speed, from 1 to 500 rpm, with a maximum weight capacity of 600 lbs. (272.2 kg) and an option of ±60-second microcorrection for adjustment of cylindricity. A sleeve retraction of up to 50mm (1.97 ") is pneumatically or hydraulically operated. Maximum weight between centers is 550 lbs. (250 kg). The swiveling, hydrostatic, direct-drive B-axis provides simultaneous interpolation of the X, Z and B axes.

Hardinge Inc.; www.hardinge.com

Drill targets deep-hole applications

Allied Machine & Engineering Corp.'s Guided T-A drill is for deep-hole drilling. The tool accepts AM200-coated inserts, or blades. The coating resists heat, which increases tool life up to 50 percent, and the tool offers penetration rates up to twice that of a gundrill, according to the company. The drill provides a tight, true position and a straight hole throughout the operation. Engineered for breaking out on an uneven surface, the drill is available in carbide-clad and chrome-plated styles and accepts the company's standard HSS and carbide T-A and GEN2 T-A blades.

Allied Machine & Engineering Corp.; www.alliedmachine.com

Air chuck grips hole saw blanks

Northfield Precision Instrument Corp.'s Model 627-W 6 "-dia. chuck has a 0.0001 " TIR and grips hole-saw blanks for turning and tapping. The 2-jaw, coolant/air blast-through chuck features a 1 "-dia. counterbore for clearance. Subjaws with two bullet-nose pins grip the blanks between two holes. The jaws are about ¾ " wide to fit between two hardened and ground circle segments mounted to the chuck face to support the workpiece during machining.

Northfield Precision Instrument Corp.; www.northfield.com

Self-adjusting bar puller for turning centers

The EZ-Puller from Accudyne Corp. is a self-adjusting bar puller used in turning centers to provide automatic operation of a CNC machine. It allows the programmer or setup person to change bar sizes in the machine without manually adjusting the tool. The bar puller functions via polyurethane springs that provide force to the pivoting arms. These arms, in turn, apply force to circular grippers at the end of the arms. The grippers rotate only under extreme load and have a serration geometry that minimally penetrates stock while maximizing grip for an accurate pull, according to the company. To set the puller for gripping and pulling bar stock, the tool is moved in the Z-axis until the grippers are at least 0.180 " past the end of the stock, then moved in the X-axis until the grippers are on centerline with the material being pulled.

Accudyne Corp.; www.ezpullerusa.com

Water-only waterjet is a low-cost option

WARDJet Inc.'s J-Series water-only waterjet cutting machine uses belt-drive technology and cuts without abrasives at speeds up to 2,500 ipm with an acceleration/deceleration rate of 0.2 m/sec.2. The waterjet is suited for companies looking to cut high volumes of parts where margins are low and tolerances are not tight. The machine has a modular design for making design changes and can accommodate material handlers, such as loading and unloading tables, as well as optical sensors to control chain-feed tables or pinch-feed rollers.

WARDJet Inc.; www.wardjet.com

Mobile cabinet maximizes storage space

Stor-Loc has added the MM33 tool storage and drawer system to its product line. The one-piece mobile cabinet measures 44 "×144 "×30 ". It has a stainless steel work surface, a steel pegboard back to allow instant access to frequently used tools and parts, and factory-installed, heavy-duty casters. The cabinet is available in various colors. Optional accessories include under-riser lighting and duplex electrical outlets.

Stor-Loc; www.storloc.com

Angle heads accommodate popular tools

Heimatec Inc. says its standard and custom angle heads are available in sizes and styles to accommodate a vast array of CNC machine tools. The angle heads have twin or double-twin sets of matched angular contact bearings and a rear radial-support bearing to provide maximum stability, according to the company. The gears have inclined teeth made from high-resistance gear steel. The teeth are hardened, ground and lapped in sets to provide smooth transmission output. The heads are made from high-tensile-strength aluminum. CAT 50, CAT 40, BT 50, BT 40, BT 30, HSK 100A and HSK 63A taper styles are available, as well as custom modifications, such as 18 " extension shafts. Standard features include 360° body rotation with positive compression locking, 90° incremental repositioning without indicating, torque up to 150 Nm, interchangeable torque arms and spindles speeds to 18,000 rpm.

Heimatec Inc.; www.heimatec.com

PCBN inserts are for machining P/M parts

Sumitomo Electric Carbide Inc.'s BN7500-grade PCBN inserts are available with five edge preparations for machining sintered alloys. The inserts are suitable for cutting P/M workpieces of any hardness, according to the company. In addition to the standard edge prep, the LF controls burrs, the LE and LS impart fine surface finishes, and the HS controls insert breakage when interrupted cutting. Multiple-tip inserts are available.

Sumitomo Electric Carbide Inc.; www.sumicarbide.com

Affordable digital CNC can be customized

The TNC 620 CNC from Heidenhain Corp. can be customized with various features and software options, giving machine tool builders and end users the ability to tailor the control to their specific needs. The DXF converter allows the user to open DXF files directly on the CNC to extract contours, point patterns and machining positions. The control comes with the HSCI interface to provide high noise immunity and simplified troubleshooting and installation, according to the company. When programming away from a machine, the control automatically takes into account machine geometry, tilting the working plane. The active chatter control function reportedly significantly reduces a machine's tendency to chatter and increases the attainable metal-removal rate during heavy cutting by 25 percent or more.

Heidenhain Corp.; www.heidenhain.com

Robot suits compact applications

The MH3F robot from Yaskawa Motoman Robotics is for compact, light-payload applications, such as parts assembly, material handling and packaging. The robot's base width of 200mm (7.87 ") allows it to be mounted in confined areas. It offers a maximum payload of 3 kg (6 lbs., 10 oz.), an 804mm (31.65 ") vertical reach and a 532mm (20.94 ") horizontal reach. A built-in collision avoidance feature enables two robots to be used together to optimize productivity. Internally routed cables and hoses enhance system reliability, according to the company. The robot's FS100 controller has open software architecture.

Yaskawa Motoman Robotics; www.motoman.com