Proactive progress

Proactive progress

Productives Times: Proactive progress. End user: Ford Motor Co., Lima Engine Plant. Challenge: Improve productivity and maximize quality when machining aluminum heads. Solution: Replaceable-head reamers with PCD cutting edges. Solution provider: Mapal Inc.

Due in large degree to proactive and progressive strategies in manufacturing, product development and finance, Ford Motor Co. has emerged as the healthiest member of the "Detroit Three" in the midst of global economic turmoil. An example on the manufacturing side is the company's Lima (Ohio) Engine Plant, which recently transitioned from building the Vulcan V-6 overhead-valve cast iron engine to producing the advanced overhead-cam Duratec 35 and 37 aluminum engines.

The engines' extensive use of aluminum contributes to manufacturing efficiency. Ron Burgei, manufacturing process engineer in cylinder head manufacturing at the plant, has worked extensively with cast iron and aluminum engine components. Compared to cast iron, "the tool life you can get in aluminum is just amazing," he said, and when PCD tools are applied, "the quality and tool life is just out of this world."

In addition, Ford continually fine-tunes production processes to maximize productivity. For the 319 (medium-silicon alloy) cast aluminum cylinder heads of the Duratec engines, one improvement effort was aimed at boosting throughput in machining of "bucket bores" in a thin-wall area of the casting. In this case, buckets are direct-acting, mechanical bucket camshaft tappets that, like the valve lifters in an overhead-valve engine, follow the movement of the camshaft lobe to open and close the valve.

The steel bucket rides in a bore cast into the head. Machining of the bore includes an ID roughing pass, which also creates the spring seat, followed by a finishing pass to achieve a tolerance of ±15µm and 0.8μm Ra surface finish.

Courtesy of Mapal

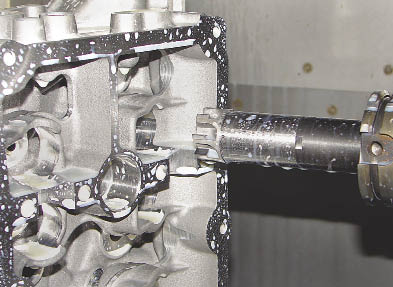

PCD-tipped, replaceable-head HPR reamers from Mapal extend tool life and permit higher cutting rates in an aluminum machining operation at Ford's Lima Engine Plant.

The plant originally finished the bores with PCD-tipped reamers mounted in shrink-fit toolholders. The reamers had nonadjustable, fixed flutes. When worn, Ford returned the entire reamer to the toolmaker for resharpening or retipping.

The problem with the tools was inconsistent performance. "Occasionally," Burgei said, "a flute was too far out of concentricity with the rest and you would get ugly retract marks in the part because the tool would flex back when retracted." In addition, new tools sometimes chattered upon initial application because of thin walls in the part and manufacturing inconsistencies in the tools.

As a result, tool life was shorter than expected. The Cross Hüller CNC machine tools used to process the heads were programmed to run each tool for a certain amount of cutting time. "A lot of tools were not reaching their programmed tool life because they would start to chatter or the retract lines would get bad," Burgei said. "You had tools that didn't run right from the start, and then you had tools that could not reach their programmed life. Those were the two major reasons for pulling the tools early."

Seeking to improve the finishing operation, Burgei consulted with the local sales representative for toolmaker Mapal Inc., Port Huron, Mich., who recommended HPR reamers. The tools have a PCD-tipped head that is clamped to a monoblock shank with a threaded spindle, which pulls the head into the shank. Positioning repeatability is within 2µm when a head is replaced, and presetting isn't required when the tool is put back on a machine. Ford returns worn heads to Mapal for lapping or tip replacement. In addition to PCD, the heads can be configured with PCBN, carbide and cermet blades and applied in materials other than aluminum.

According to Burgei, Mapal had tooling at Ford before the HPR application to machine valve seats and cam bores. "Those are probably the two most difficult operations we do on the head," he said.

Special tools for those applications are premium-priced and require a precise setup; "they take a high skill level in the toolcrib," Burgei said. However, the HPR reamers are about half the cost of the original PCD-tipped reamers, "and there is no setup," he added. "All you do is clamp the head on and away you go." Changing the head alone reduces costs. "We just send the heads back for reconditioning and keep the toolholder body here," Burgei said.

The new reamers improved machining performance and lowered tooling costs. "We've gotten about four times the life that we were getting from the PCD-tipped reamers," Burgei said. "Where we ran maybe for 4 or 5 weeks with the other tools, we are now running 4 or 5 months."

Cutting rates improved as well. "We are running at 5,500 rpm and an 8,620-mm/min. feed, two times faster than what we did with the previous reamers," Burgei said.

Extended time between tool changes and more productive cutting parameters have enabled the plant to increase throughput without additional capital investment in machine tools. "By working on bottleneck operations and increasing feed rates—doing all the right things—we have been able to take a line that was bought to produce 58 parts an hour and consistently run 75 parts an hour," Burgei said.

The manufacturing process improvements are just one element of Ford's recent success. Burgei said: "We are doing a lot of good things. It's nice to say we can machine these parts well, and hopefully we can win in the marketplace as well. A couple weeks ago we got one of those initial-quality surveys that are done all the time and it said we are better than Toyota. It's been a long time coming."