Protect processes, collect data

Protect processes, collect data

CoroPlus ProcessControl predicts, detects and reacts to machining process problems within milliseconds

To predict, detect and react to problems with machining processes within milliseconds, Sandvik Coromant Co., Fair Lawn, New Jersey, developed CoroPlus ProcessControl. At the same time, the monitoring system can collect data to correct and improve inefficiencies in a process.

"The main functionality is it automates data collection and analysis," said Jeff Rizzie, director of digital machining. "It gathers the data directly from the machine tool and basically makes a decision on whether your machining process is stable or needs to be adjusted."

A collision detection function determines when a machine has a collision and then quickly shuts down the machine. The function is not application-dependent. If a crash occurs, traditionally a machinist hits the stop button. But by the time that is performed manually, the damage is done, he said.

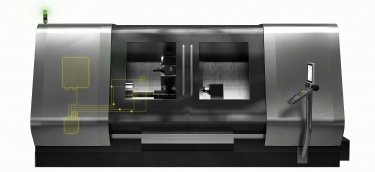

The CoroPlus ProcessControl process monitoring system is designed to increase machining security, such as on this universal turning center. Image courtesy of Sandvik Coromant

A tool guard function works similarly but in more finite terms. Rizzie said it looks for broken or missing tools and detects tool force overload to decide when a worn tool needs replacement. The function uses a combination of machine data, such as power and drive data, and data from a vibration sensor mounted on a spindle nose or turret.

"What we're looking for are patterns or anomalies," he said. "Like any kind of data analytics, we're looking for those patterns that will tell us if everything is running properly or if there is a possible tool breakage situation."

Data logging records profiles of tool behavior during machining, said Niels Bredick, senior solutions specialist of process control. Analyzing tools can extend their lifetimes. Using individualized sensor profiles and comparing them helps to better understand a problem with a process. Data can be used to replace a tool before something bad occurs, potentially saving thousands of dollars.

"Our equipment can be applied to any type of machine tool or robotic- or machine-type movement," he said.

Bredick said the system increases tool life and reduces cycle times and scrap.

"What ProcessControl does is very, very powerful and provides tremendous value," Rizzie said. "The real interesting part of ProcessControl is not what it does today but what it does in the future. What can we do with that data?"

The performance data the application gathers provides insight into how machines function as planned versus as optimized. He said the long-term objective is to build a knowledge base for engineers.

"You're taking data, using it, collecting it and analyzing it for future use," Rizzie said. "It can be used to find flaws in the process of using a tool as well. You can find areas of early chatter before you ever feel it."

The size of the company, batches or components doesn't matter, Bredick said. The customizable system can diminish damages, reduce downtime costs, provide process security and boost productivity.

For more information about Sandvik Coromant, call 201-794-5000 or visit www.sandvik.coromant.com.