Selecting the correct drilling tool

Selecting the correct drilling tool

Economics of Drilling Sidebar: Selecting the right drill to reduce costs and enhance productivity depends on the material and production requirements.

The right drilling tool can significantly reduce costs and enhance productivity — but the correct choice depends on the material and production requirements.

Depending on application requirements, there is a place for both multipurpose and application specific drilling tools. Versatile, multipurpose drilling tools are designed to work on a wide range of materials, and are especially suitable for common materials ranging from carbon steels, stainless steels, aluminum and copper alloys, and, to some extent, certain nickel alloys. To minimize tool changes, multipurpose drilling tools can be beneficial to job shops with a higher mix and lower volume of parts.

Alternatively, application specific drills with a specialized design may be a better choice when drilling challenging materials such as titanium and nickel alloys, Inconel and high-strength and hardened steels and hard castings. These tools have been designed to provide options for specific challenging materials, and to maximize hole quality in longer production runs. These higher performance tools with specialized geometries are the go-to choice for specific material groups or applications where cycle time is critical.

Ultimately, if you're ever unsure about which tool to select, reach out to your tooling supplier. The following real-world application use cases demonstrate how consulting with your tooling supplier for advice and application testing will greatly assist with making the optimal choice.

Case Study 1: Abrasive Steel Dies

A precision electrical components manufacturer had been using a high-speed drilling strategy to drill extremely abrasive 25-30 Rc CPM10V steel dies with high-speed steel and cobalt drilling tools. Each part required 100 drilled holes and the manufacturer produced about 50 parts per job for a total of 5,000 holes. The manufacturer only achieved two holes per drilling tool, using 2,500 tools to complete the job at a total tooling cost of $19,575.

EMUGE recommended the manufacturer rework and optimize the speeds and feeds to test an EMUGE solid carbide MultiDRILL multipurpose drilling tool that cost more than the tool the company had been using. After testing, the manufacturer put the MultiDRILL into production and saved $57,570 on the job when factoring in all costs including tooling, labor and regrinds.

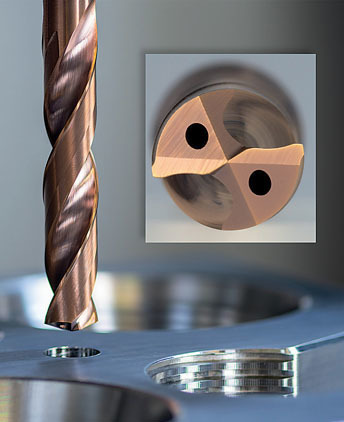

Now 400 holes are being drilled per tool compared to two holes with the original tool. The MultiDRILL features concave cutting edges, providing higher chip shearing ability and a tightly controlled edge preparation process that provides consistent performance and long tool life. The drills are constructed using specialized carbide grades that make the tools harder than conventional carbide grains for drilling, yet still retain the ability to withstand shock and chipping. Also, the tool coating has high hardness that reduces friction at elevated temperatures.

The EMUGE InoxDrill boasts a solid carbide construction, a custom ALCR-T89 coating and polishing process, and a single margin design. EMUGE-FRANKEN

Case Study 2: Inconel Mounting Blocks

A CNC Job Shop that makes components for the power generation, defense and aerospace industries uses an application specific EMUGE InoxDrill tool together with the EMUGE FPC toolholder to cut costs and improve process consistency and quality. InoxDrill is saving over 80% on the job with a total savings of $19,800.

Two drilled holes are required in a 36 Rc Inconel 625 mounting block, which is produced in volumes of 400 per run for a total of 800 holes. The former drilling operation utilized a TiN-coated solid carbide drill that required a slow feed rate and a pecking program cycle. The prior method was inconsistent and resulted in broken drills and scrapped parts.

The manufacturer's goal was to improve throughput and increase speed, so they contacted EMUGE for assistance. EMUGE tested its InoxDrill tool in a highly rigid EMUGE FPC toolholder. InoxDrill features solid carbide construction, a custom ALCR-T89 coating and polishing process, and a single margin design that reduces material adhesion and provides excellent hole guidance, ideal for material with elastic memory that can compress down on a drill. A concave main cutting edge combined with optimized cutting-edge preparation enables consistent performance at very high feed rates, optimal chip forming, and increased tool life. The special coating provided a 15% increase in surface hardness, a 22% increase in maximum operating temperature compared to AlTiN-based coatings, and a 200% increase in tool life during testing.

FPC Mill/Drill Chucks enabled optimal rigidity, vibration dampening, concentricity, machining speed, and tool life versus conventional chuck technologies for milling and drilling applications. The solution runs reliably with increased productivity and no tool breakage. The manufacturer can now drill 360 holes using the EMUGE InoxDrill and FPC toolholder versus eight holes with the original drill and toolholder.

Case Study 3: Austenitic Stainless Steel

A manufacturer attempted to use a solid carbide drill that wasn't optimally designed for heat-resistant materials, and didn't include coolant-through capability for drilling a highly abrasive form of austenitic stainless steel. So the shop implemented EMUGE's application-specific InoxDrill. Running at a higher feed rate and overall drill penetration rate, the InoxDrill resulted in more than 30% cost savings and achieved a tenfold increase in total hole count.

—EMUGE-FRANKEN USA