Shrink-fit chucks enhance precision

Shrink-fit chucks enhance precision

Productive Times Challenge: Find a suitable toolholder to handle precision machining. The Solution: Shrink-fit chucks.

END USER: Starrag USA Inc., (859) 534-5201, www.starrag.com.SOLUTION PROVIDER: Haimer USA LLC, (630) 833-1500, www.haimer-usa.com.CHALLENGE: Find a suitable toolholder to handle precision machining.SOLUTION: Shrink-fit chucks.

Machining centers from Starrag AG are available as turnkey solutions, including software, clamping fixtures, toolholders and peripheral accessories. The company, located in Rorschacherberg, Switzerland, provides 5-axis machining centers capable of high metal-removal rates to produce turbine blades, impellers, blisks and other structurally complex parts for industries such as aerospace and energy. (Starrag USA Inc. is located in Hebron, Ky.)

Because the company has been using a 30,000-rpm spindle for 20-plus years, it realizes the importance of toolholding. "In the past, our cutting tools were usually clamped with Weldon or whistle-notch holders and collet chucks, which led to many problems because of the insufficient runout accuracy they provide," said Patrick Rutishauser, head of application engineering at Starrag. "At high rotational speeds, even small deviations can lead to poor milling results, inferior surface quality and tool and spindle wear. Also, the geometry of these toolholders has many interfering contours, which make it impossible to reach deep cavities with minimally clamped tools."

According to Patrick Rutishauser, head of application engineering at Starrag, Haimer professionalized the shrink-fit process. Images courtesy Starrag.

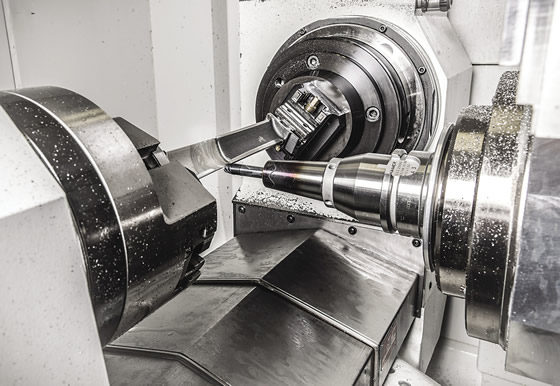

Starrag utilizes Haimer shrink-fit chucks due to their rotationally symmetric clamping bodies.

Starrag determined through R&D efforts to use shrink-fit chucks due to their rotationally symmetric clamping bodies. These chucks have fewer interfering contours and a high runout accuracy. As a result, Starrag engineers came across Haimer GmbH, Igenhausen, Germany, a shrink-fit toolholder manufacturer. (Haimer USA LLC is located in Villa Park, Ill.)

Haimer makes all its shrink-fit chucks, including standards, out of heat-resistant steel. For specific machining requirements, Haimer offers specials. The Power Shrink Chucks, for example, are suitable for special high-speed or high-precision milling applications.

Rutishauser explained that there are generally two procedures during blade production, starting with a roughing process where the chuck operates with a damping component to achieve a high cutting depth and feed. "During the finishing process, however, there aren't any strong cutting forces," he said. "At this point, a high runout accuracy and the balancing quality are important. The Haimer Power Shrink Chucks are suitable for both processes and, if the cutting gets even tougher, we simply switch to the heavy-duty chucks."

When roughing and finishing titanium and other difficult-to-cut materials, cutting forces can be very aggressive on the interface between the machine spindle and the toolholder. "In the end, the key element is the part quality. It has to be perfect from the very beginning, because even the titanium blanks cost a small fortune," Rutishauser said. "This is especially true regarding the surface quality, which constitutes an important factor. This is due to the fact that the turbine blades need a very precise structure in order to be very energy efficient. Nowadays, you can get the desired structure through milling and without any additional regrinding." Starrag can achieve a surface quality of 0.4 µm Ra to 0.8 µm Ra, he noted.

To heat toolholders for shrink fitting, Starrag uses a Haimer Power Clamp Profi Plus NG in its Centre of Production Excellence (CPE). It is suitable for all 3mm- to 50mm-dia. (0.118 " to 1.968 ") HSS and solid-carbide tools with an H6 shank tolerance. It is equipped with a patented double-coil technology, which means that the coil adapts itself to the length and diameter of the chuck. During the process, only the shrinkable area is heated, which significantly reduces the heating and cooling time (via contact cooling).

"Haimer shrink-fit chucks are part of our standard equipment, because they offer the best conditions for reliable cutting, which people expect from us," Rutishauser said.