Streamlining work flow

Streamlining work flow

CHALLENGE: Reduce setup and cycle times while meeting customers' demands for high-quality parts. SOLUTION: Two horizontal machining centers. END USER: Reinhold Industries Ltd., (780) 434-8552, www.rilflo.com. SOLUTION PROVIDER: Methods Machine Tools Inc., (877) MMT-4CNC, www.methodsmachine.com.

CHALLENGE: Reduce setup and cycle times while meeting customers' demands for high-quality parts.

SOLUTION: Two horizontal machining centers.

END USER: Reinhold Industries Ltd., (780) 434-8552, www.rilflo.com.

SOLUTION PROVIDER: Methods Machine Tools Inc., (877) MMT-4CNC, www.methodsmachine.com.

From reducing cycle times to deploying automation, part manufacturers are working to make their operations run as efficiently as possible while still producing high-quality parts. One such manufacturer is Reinhold Industries Inc., Edmonton, Alberta, which produces flow control components in its 26,000-sq.-ft. facility. The parts range from ¼"(6.35mm) to 16" (406.4mm) in diameter. Processes vary from drilling and milling wellhead components to producing aluminum parts for the plastics industry.

With such a broad array of parts, sizes and processes, achieving a high level of accuracy and efficient machining times had become big issues because of the need to perform multiple setups in various machines. These factors led the company to seek ways to streamline its operations and improve work flow, according to Reinhold President Marcel Klutke.

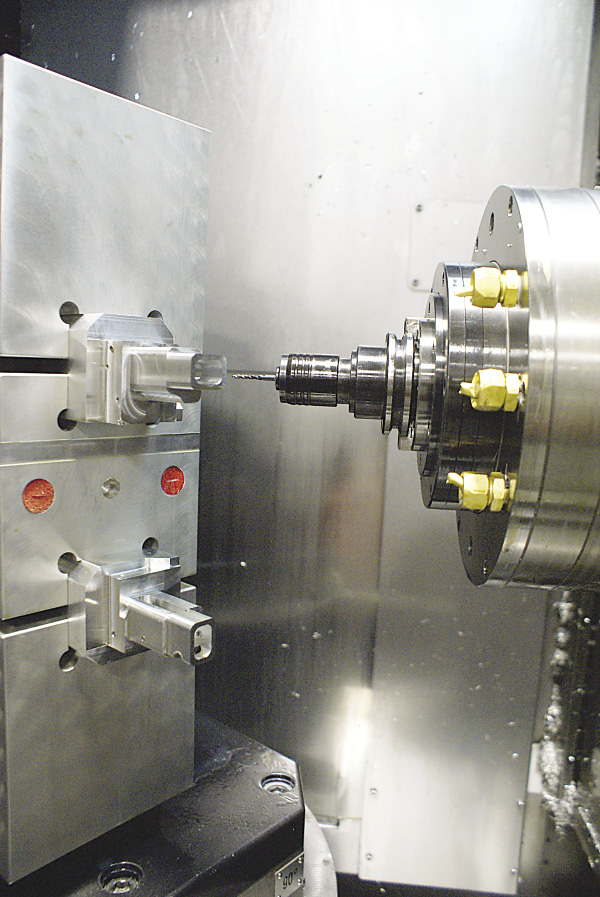

Reinhold Industries machines plastic-injection cylinder bodies held on a KIWA tombstone in a KIWA HMC. Image courtesy Reinhold Industries.

One part of the solution was to find a machine tool that could produce parts to meet customers' stringent specifications and deliver them on time. "Our customers depend on us for quality and reliability," Klutke said.

As part of the decision-making process, he looked at horizontal machining centers over a 6-month period, touring several machining facilities and speaking with owners and operators.

About 10 years ago, Reinhold started with a six-pallet KIWA Model KNH-426x horizontal machining center manufactured by Japanese machine tool builder KIWA Machinery Co. Ltd. Because Reinhold was pleased with the HMC's performance, it purchased a two-pallet KIWA KH-45 HMC, which is expandable to eight pallets in the field, from machine tool supplier Methods Machine Tools Inc., Sudbury, Mass.

"We received a Japanese-made machine with a high-speed, 4-axis, CAT 40, BIG Plus spindle and the ability to add pallets and tooling with very little effort at an affordable cost," Klutke said.

A selection of parts produced by Reinhold Industries. Image courtesy Reinhold Industries.

He added that the repeatability of the HMC enables Reinhold to easily hold part dimensions, and the company is able to spend more time making chips than setting up the machine. "Complex parts are no longer an issue with KIWA's versatility and quick changeover. Setup used to take us 4 to 5 hours, but now it takes less than an hour."

Reinhold uses the KIWA HMCs to produce a variety of parts, Klutke noted, such as 15"×15"×15" crosses and aluminum air-distribution manifolds and mounting supports, while the full B-axis eliminates the use of multiple machines for numerous operations. Parts that previously required five or six operations in multiple machines, lathes and machining centers now run in two operations simultaneously on KIWA tombstones. "They have eliminated the accuracy issues we had when using multiple machines and operations," Klutke said, adding that run times are shorter as a result.

"Across the board, the KIWA machines have reduced handling and allowed us to achieve, on average, a 20 percent increase in productivity and, in some cases, up to 40 percent," Klutke said.