Taking wire EDMing to the next level

Taking wire EDMing to the next level

Short, simple setups paired with automation boost wire EDM utilization.

Thanks to continuous improvements in machine technology, wire electrical discharge machine (EDM) cutting speeds are the fastest they have ever been. While this is most beneficial in shortening part cycle times, it only goes so far in terms of increasing machine output. However, reducing part setup times together with automation can take wire EDM output and utilization to the next level – in some instances, that is a jump from 2,000 to 6,000 hours of annual machine utilization.

The key to shorter EDM setup time is to accomplish as many of the setup processes as possible outside of the machine to minimize the need to interrupt cutting. Three common steps comprise the basic part setup process for wire EDM: determining the part's location, ensuring that it is flat and precisely locating its center, edges or corners.

To determine an approach to setup reduction and the eventual automation of EDM operations, a shop should analyze how it accomplishes setup manually and determine the elements of their setup that consume the most time. Those elements should then be the focus of initial setup reduction efforts.

Traditional wire EDM setup involves placing the part to be cut on the machine table between toe clamps and tapping it straight and flat while measuring its location and features with a manual dial indicator. The process is slow, tedious and subject to inaccuracy and error.

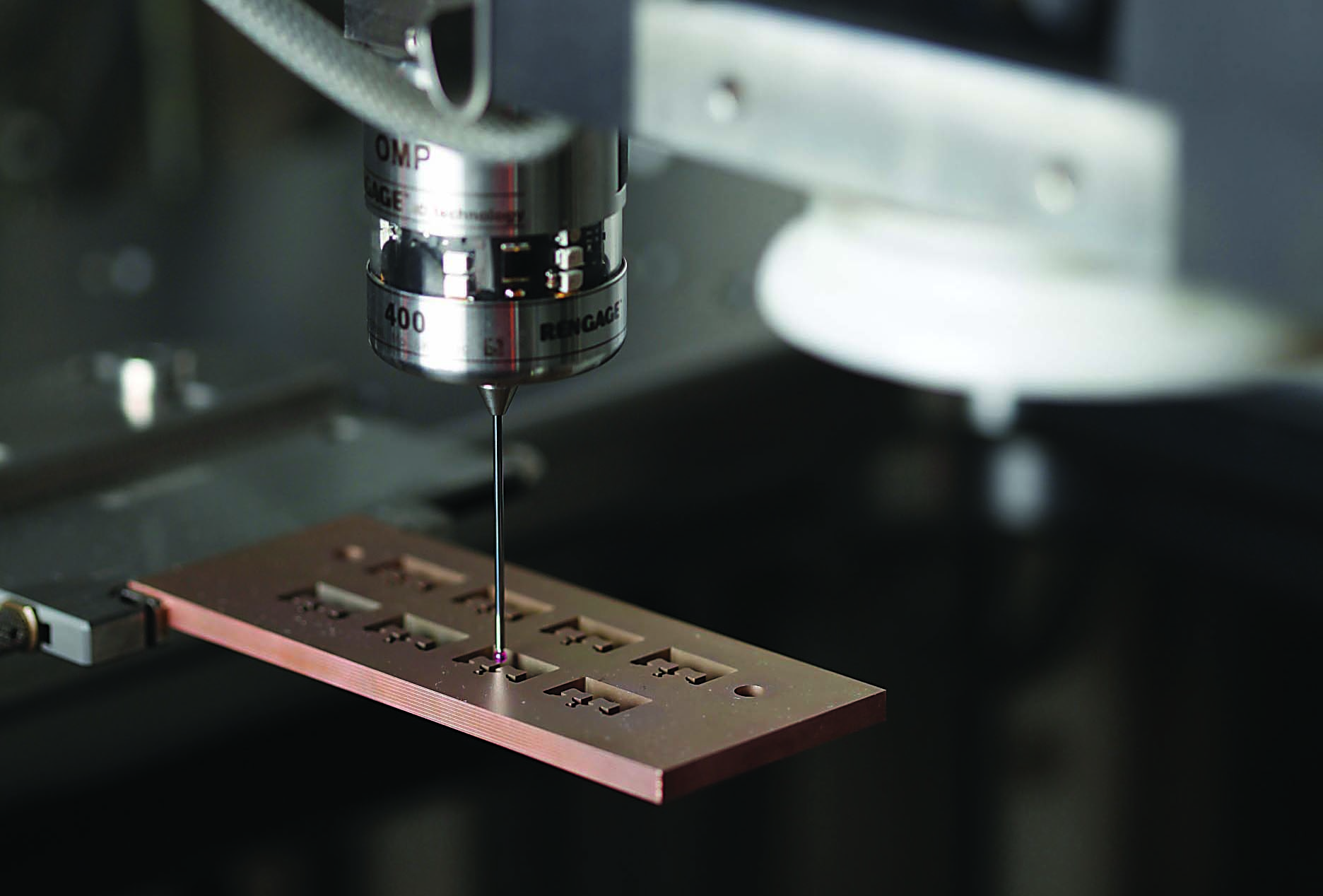

A probe performs in-process gaging on a wire EDMed part. Image courtesy of GF Machining Solutions

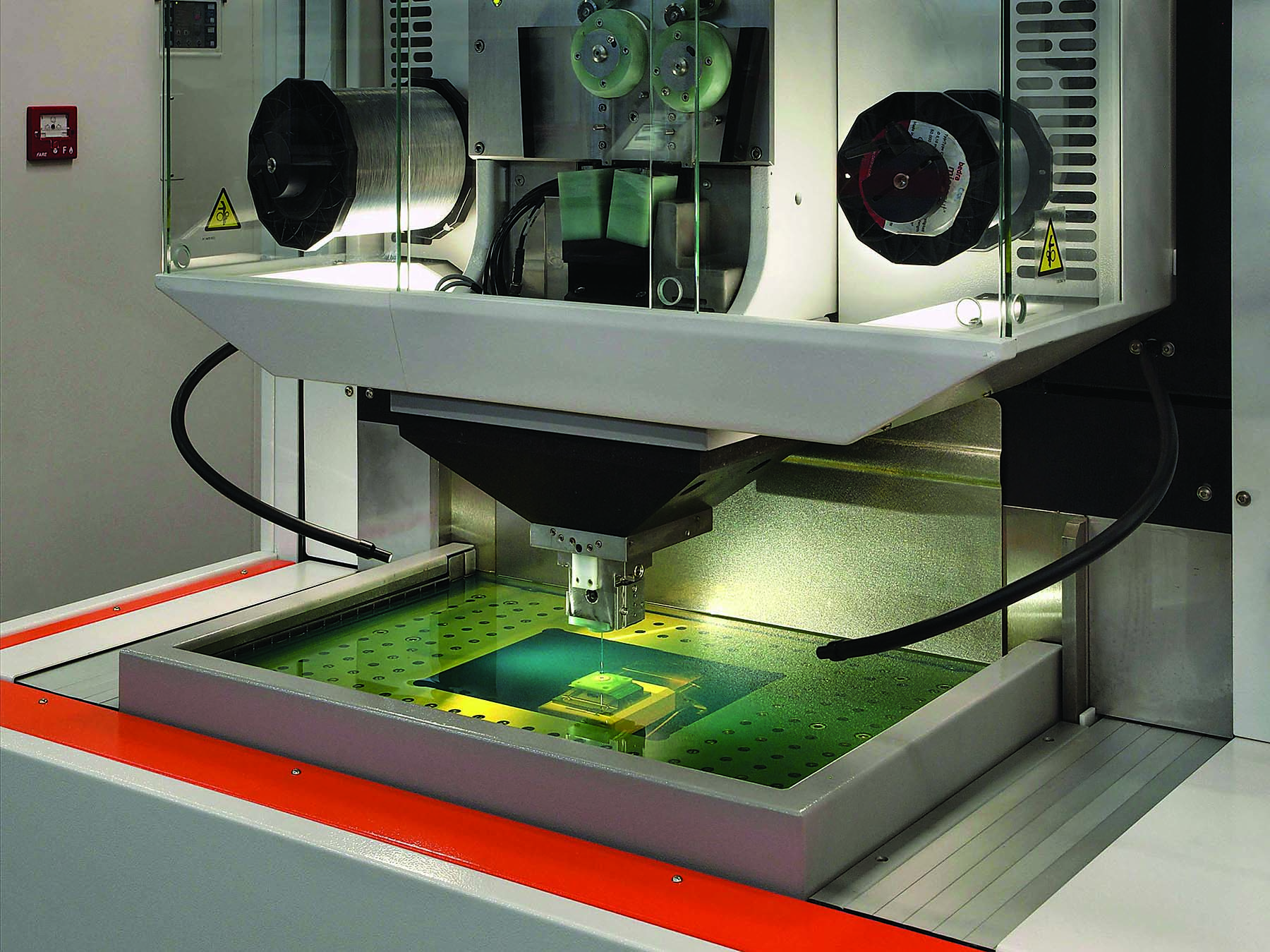

To allow for part setups outside of the EDM, modular workholding systems with a base unit mounted in the machine and mating work pallets ensure that parts, when loaded on the pallets and into the machine, will always be in the same position relative to the EDM wire. Such systems allow shops to measure and locate parts at independent presetting stations while the EDM continues to work uninterrupted.

With the implementation of a universal tooling system that reduces excessive setup time, the same machine achieves significant gains in productivity and ROI. The System 3R WorkPartner 1+ (WPT 1+) modular automation system for wire EDMing, for instance, can add two hours of unattended machine capacity per day and reduce setup time to one hour on an eight-hour shift.

System 3R is the original manufacturer of brand-agnostic, universal tooling systems and open architecture automation compatible with every type of process and machine tool, regardless of age or brand. Any shop can utilize, modernize and benefit from System 3R solutions.

Additionally, System 3R tooling provides universal compatibility that extends to all manufacturing processes – such as moving workpieces from EDM to milling in a single setup – with no need to relocate and re-reference parts. This stable, exact reference allows manufacturers to preset parts away from machines for minimum downtime. It also helps reduce the stacked tolerances typically associated with repeated part locating and referencing. System 3R tooling remains repeatable within microns even after a million clampings.

The System 3R WorkPartner 1+ modular automation system for wire EDMing can reduce setup time to one hour on an eight-hour shift. Image courtesy of GF Machining Solutions

This concept lets users define each machine's zero point – once and only once – to establish fixed references for all machines in the workshop. The system converts internal setup time to external setup time, which reduces the time machines stand idle in preparation for different jobs.

Acquiring part measurement data accurately and consistently then communicating it to the EDM further facilitates setup time management. Manual dial indicators can wear and provide inaccurate data, and operator error can also hinder measurement precision. To maximize accuracy and reliability of the data, a shop can mount the part on a coordinate measuring machine (CMM) for precise measurements and data tracking.

The CMM can then post that data to the machine's control. An example is set point data used to determine the correct starting point for the cutting operation. Additionally, loading multiple modular workholding pallets at the presetting station and using multiple mating bases in the EDM allows for serial bulk machining for further improvement in machine utilization.

Automating measurement inside the machine is yet another setup time reduction tactic. Current wire EDM machines can perform contact sensing and have automatic edge- and center-finding capabilities. Utilizing the measuring capabilities of the EDM to gather the part's location data is a step toward full setup automation.

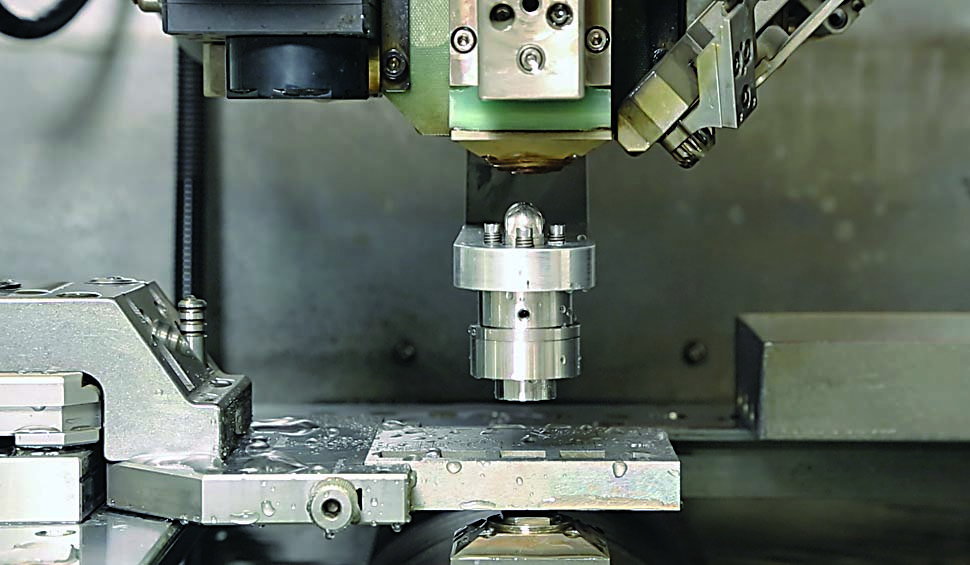

Automatic wire changers, such as on the CUT 2000S from GF Machining Solutions, feature twin wire spools. This allows multiple gauges of wire to be used in the same job. Image courtesy of GF Machining Solutions

In an advanced example of this technology, wire EDMs from GF Machining Solutions offer Renishaw 3D probing, a factory-installed hardware and software option that has a touch probe integrated into the upper wire head. The probe measures the location, dimensions and flatness of workpieces located on the EDM worktable. Unlike most EDM measurement programs, 3D setup provides Z-axis data as well as X and Y measurements.

The 3D setup probing performs a three-point touch routine that establishes the part's top plane. The machine orients the EDM wire to be perpendicular to that plane. Even if the plane is at a compound angle – tilted in two directions – the software aligns the wire to cut as if the plane were flat.

Another key to minimizing non-cutting setup time is to make every job as simple as possible. Tooling standardization is one way to simplify processes. To do so, many EDM shops standardize on 0.010"-diameter brass wire. However, a dual wire machine can provide flexibility to quickly switch from one wire type to another when necessary or can be loaded with the same wire on both spools to provide enough capacity to ensure that the wire will not run out in long untended runs.

Once a shop achieves automated wire EDM setups, they can focus on factors that affect the adoption of lights-out machining, one of which is slug management. The issues here are unique to wire EDM. Wire EDM produces slugs of uncut material, and they must be effectively removed.

With automatic slug management, shops gain true lights-out capability from their wire EDM machines. Image courtesy of GF Machining Solutions

A partial solution involves programming the machine's CAM system to cut the part while leaving very small (up to about 0.100" thick) tabs attaching the slug to the workpiece. After machining is complete, the operator cuts off the tabs and removes the slugs.

Some wire EDMs have automatic slug welding capability that welds the slug in place using small residual deposits of brass from the cutting wire. When cutting is complete, the slugs are removed by hand.

Another method employs what is called an early-and-late strategy. In the late stage, EDM roughing passes involving tabs occur untended overnight. In the early stage, operators remove tabs and slugs during the day. Although these manual slug removal operations limit the ability to operate fully untended, they can be consolidated and scheduled for overnight production.

An alternative to the early-and-late strategy is an automated slug system such as the GF Machining Solutions Automatic Slug Management (ASM) innovation. This function uses either an electric magnet or a suction system to grab and remove slugs out of workpieces and deposits them into a basket inside the work tank in a fully automatic operation. With ASM, shops gain true lights-out capability from their wire EDM machines.

Full untended wire EDM operation is possible with the right workholding, machine technology and job strategies. Applying tactics and machine features to reduce setup time together with automation allows for lights-out wire EDM production to boost utilization by 6,000-plus hours per year.

GF Machining Solutions offers innovative Milling, EDM, Laser texturing, Automation, and Customer Services solutions. Reach them at 800-282-1336 and www.gfms.com.