Thick as a brick

Thick as a brick

The 'thickest' PVD coating for cutting tools.

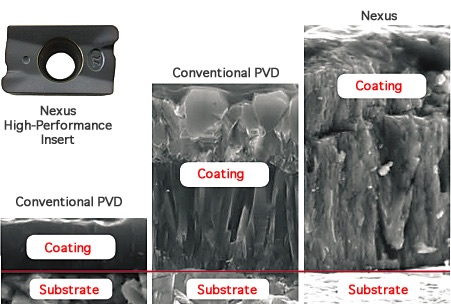

The thicker the PVD coating is on an insert, the longer users expect it to last. But a coating that is too thick tends to flake, reducing the coating's effective life, according to Mike Raper, national sales manager for Techniks Inc. That is why most manufacturers' PVD coatings are only 4µm thick, he noted. However, the toolmaker's Nexus line of milling, turning and boring inserts have a PVD TiAlN LT10 coating up to 8µm thick for milling and a LT1000 coating up to 14µm thick for turning.

Courtesy of Techniks

The thickness of the Nexus Magia PVD coating compared to a conventional PVD coating and a conventional CVD coating.

Raper explained that the unique PVD formula for the Magia coating, developed by partner Lamina Technologies SA, Yverdon-les-Bains, Switzerland, prevents flaking while enabling the highest possible adhesion of the PVD to the submicron grain carbide insert, which has a special edge preparation. Prior to coating, the inserts are subjected to a micro-sandblast technique to hone the cutting edge radius to within a ±5µm tolerance. This process takes the place of brush honing, which creates an uneven edge, according to Raper.

"Our coating ends up being smoother and more uniform," he said, adding that a post-coating polishing treatment also reduces friction.

With traditional coatings, increasing the hardness usually means reducing toughness and vice versa. Nexus' nanocomposite coating structure, LT1000, has a high hardness and toughness at the same time, according to Chris Deis, director of marketing for Techniks. He claimed that LT1000 is the thickest supernitride PVD coating on the market and provides greater thermal insulation and more resistance to plastic deformation and shock than CVD or traditional PVD coatings.

Courtesy of Techniks

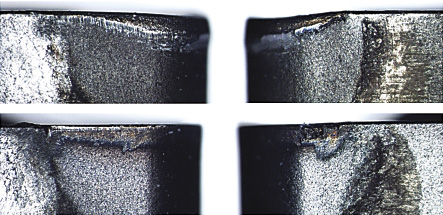

A comparison of tool life for the Nexus CMMG 120408 NN MG10 insert (bottom two) vs. another toolmaker's brand (top two) after wet machining 42CRMo4 at a cutting speed of 660 sfm, a feed of 0.020 ipm and a 0.079 " DOC for 22.0 minutes (Nexus) and 11.5 minutes (other brand).

In addition to extending tool life, the Nexus inserts are suitable for machining multiple materials, including low-carbon steel, stainless steel, alloy steel hardened up to 60 HRC, cast iron, titanium and heat-resistant superalloys. The company offers a separate LT05 grade coated with chromium nitride for machining aluminum alloys, but the other Nexus LT grades are also effective in aluminum with a silicon content higher than 8 percent, Raper added. "You can go from material to material and job to job with the same insert," he said. "With us, you buy an insert for its shape, not by grade for a certain material."

Multiple-material machining ability not only reduces cutting tool inventory, it eliminates guesswork when selecting a grade, increases production efficiency and flexibility and reduces costs, according to the company. "Machinists don't have to go looking for inserts every time they change jobs," Raper said. "They just go with what they've got in the machine and it works extremely well."

For more information, contact Techniks Inc., Indianapolis, at (800) 597-3921 or www.techniksusa.com/nexus.