This toolholder’s got smarts

This toolholder’s got smarts

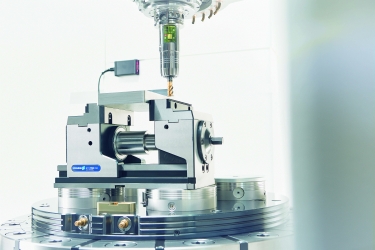

The iTendo hydraulic expansion toolholder helps reduce vibrations, chatter marks and tool failure.n

An intelligent toolholder that directly monitors machining processes and provides real-time control of cutting parameters has been developed by Schunk and startup Tool It GmbH, Vienna. The iTendo hydraulic expansion toolholder helps reduce vibrations, chatter marks and tool failure.

The toolholder monitors the machining process at the tool/workpiece interface, fully using the potential of integrated process monitoring right where the chip forms. Schunk calls this strategy "closest to the part," in which intelligence is incorporated into the first wear-free element of the machine equipment that is adjacent to the workpiece.

"The iTendo is a milestone in toolholder technology," said Schunk CEO Henrik A. Schunk. "For the first time, we combine the outstanding mechanical properties of our flagship Tendo with the possibilities of digital process monitoring."

The toolholders with integrated process intelligence have the same interfering contours as conventional toolholder mountings. Applying coolant is still possible. Equipped with a sensor, 10-hour battery and transmitting unit, the system records the process directly in the tool and wirelessly transmits data to a receiving unit. Data is then sent via cable to a control and evaluation unit for analysis. An algorithm continuously determines ideal parameters for process stability. Depending on the application, a web service can be used to define the exact limits and, if they are exceeded, corresponding reactions. Data from the entire process remains in the closed control loop of the machine to ensure high-level data security.

The smart iTendo enables real-time process monitoring and control directly in the tool. The geometry and performance data of the toolholder remain unchanged even with a sensor. Image courtesy of Schunk

"Embedded systems technology combines the highest degree of process transparency with the potential of autonomous process control without users having to do without the quality and performance of proven precision toolholders," said Friedrich Bleicher, founder of Tool It and managing board director of the Institute for Manufacturing Technology at Vienna University of Technology, which participated in the design process.

"We hope to offer an economical closest-to-the-tool, real-time data feedback and data collection system," said Matthew Panosh, group manager of toolholding at Schunk.

While still in the early release stage, the manufacturer is working closely with other companies to expand applications for the toolholder.

The sensor mounts in the holder, allowing more sensitive detection of vibrations in the cut, Panosh said. Other cutting monitoring systems, such as spindle-mounted systems, are great for larger tools where a lot of vibration is created but tend to taper off as a tool becomes smaller. The iTendo toolholder offers vibration detection and the setting of vibration limits for small-diameter tools. If vibration in the cut reaches an unacceptable level, the cut can be optimized while maintaining acceptable vibration levels.

Additionally, the intelligent toolholder shortens the learning curve to find the "sweet spot" cutting parameters for producing complex parts, Panosh said. An operator has the ability to quickly recognize and correct unforeseeable instabilities in the cutting process.

For more information about Schunk, Morrisville, North Carolina, call 919-572-2705 or visit www.schunk.com.