A twin-turret approach to machine tool stiffness, stability

A twin-turret approach to machine tool stiffness, stability

Two rotary axes beat 2' of stacked linear axes. That's the idea behind the new Twin Turret Generator (TTG) machine tools from Cranfield Precision. According to the company, the TTG machine offers a stiff and thermally stable design that improves machining precision and repeatability.

Two rotary axes beat 2' of stacked linear axes. That's the idea behind the new Twin Turret Generator (TTG) machine tools from Cranfield Precision. According to the company, the TTG machine offers a stiff and thermally stable design that improves machining precision and repeatability.

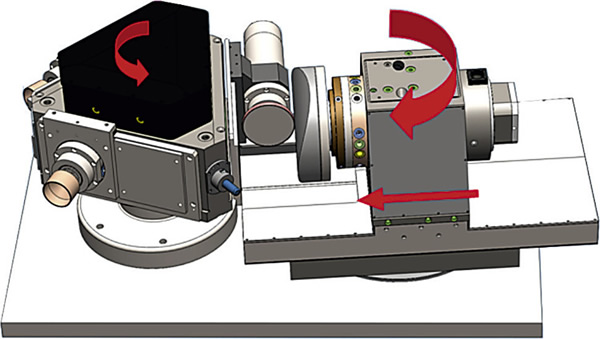

While conventional machine tools mainly use stacked linear axes to control motion, the TTG's patented "twin-turret" design employs two stiff rotary axes and a short linear infeed axis to produce relative motion between the cutting tool and workpiece.

The TTG design from Cranfield Precision coordinates the motion of two rotary axes and a short linear axis for high-precision machining. Image courtesy Cranfield Precision.

To explain key differences between the TTG and conventional machines, Mark Stocker, Cranfield's division manager for grinding, uses the concept of the stiffness and thermal "loop," which refers to the path leading from the tool to the base of the machine and then back to the component being machined. "The longer that path is, and the more axes it runs through, the less stiff the loop will be," Stocker said.

And that path is often very long. "If you look at a conventional machine," Stocker said, "you've got lots of axes stacked one on top of the other, going down to a bed that could be a couple of feet from where the tool is."

As for the thermal loop, he continued, all surfaces the loop runs through are exposed to grinding coolant, air temperature or both. So the longer the path traced by the thermal loop, the more susceptible the system will be to thermal distortions—and the more motion there will be between tool and component if the exposed surfaces heat up or cool down.

The TTG design boosts machine stiffness and reduces thermal distortions by shrinking the stiffness and thermal loop. In addition, the design includes a stainless steel tray surrounding the turrets that carries coolant to gutters around the machine. As a result, coolant never touches the machine base, which is "unique to our machine configuration," Stocker said.

By contrast, he noted, it is impossible to prevent grinding coolant from touching the base of conventional machines. When coolant, warmed by the grinding process, touches the top of a machine base, the top warms up relative to the bottom, causing the base to bend.

Cranfield's new machine tool comes in two versions: the TTG100 for parts up to 100mm (3.94") in diameter and the TTG400 for parts up to 400mm (15.75") in diameter. Key TTG capabilities cited by Cranfield include grinding to submicron tolerances, as well as milling, polishing, diamond turning and metrology.

For more information about Cranfield Precision, Bedford, U.K., visit www.cranfieldprecision.com or call +44 1234-312820. Or contact Fives Landis Corp., Hagerstown, Md., at (301) 797-3400.