Wheels Up

Wheels Up

New materials, the need for lightweight parts and the burgeoning size of some aircraft challenge manufacturers of landing gear components.

New materials, the need for lightweight parts and the burgeoning size of some aircraft challenge manufacturers of landing gear components.

Sleek wings and powerful engines are familiar images of flight. An aircraft's landing gear, however, is just as essential for successful air travel. A fully loaded, double-deck, 800-passenger Airbus A380 jetliner weighs about 1.3 million lbs. Aloft, those 650 tons are supported by the magic of aerodynamic lift. But movement on the ground, including takeoff and landing, are handled by components that are complex, remarkably strong and quite large.

For example, Goodrich Corp., Charlotte, N.C., said the undercarriages for the main landing gear it supplies for the A380 are 18½ ' tall. As the size of some aircraft grows and demand for fuel efficiency increases across the board, manufacturers of landing gear face the challenge of making the large, complex assemblies both as strong and as light as possible.

Courtesy of Boeing

A landing gear test on the Boeing 787 Dreamliner.

Like all manufacturers, landing gear makers are dealing with supplier consolidation and implementation of lean initiatives. Said John Cerps, manufacturing engineering manager at the Toronto facility of global landing gear provider Messier-Dowty International, Vélizy, France, "over the last 5 to 10 years, there has been a major transition for all major subsystem suppliers to airframe manufacturers. Everyone is trying to offer an integrated system as opposed to individual parts or subassemblies."

Cerps said Messier-Dowty Inc. works with its customers to determine the space available for the landing gear, the desired configuration and functional details, and then provides a plug-in solution. "We are giving them the landing gear system," Cerps said, "which is all the electrics, hydraulics and pneumatics, complete with wheels, brakes and tires, the steering system and braking system. The landing gear is bolted into the aircraft and all they have to do is connect the electrics, hydraulics and pneumatics."

Cerps estimates that the Toronto facility, whose capabilities include design, development, production and support of landing gear for military, business and commercial aircraft, manufactures about 10 percent of the parts for the systems it provides. For the rest, it relies on a network of proven suppliers. Cerps said his facility machines "all of the parts that are very complex, which require an investment in specialized machine tools."

Courtesy of Messier-Dowty

This business jet's main landing gear is typical of the integrated landing gear systems provided by Messier-Dowty.

Also like other manufacturers, Messier-Dowty is "in competition with ourselves; we are mandated by our corporate head offices to continually improve," Cerps said. For example, he described efforts to optimize production of a family of landing gear components consisting of four pistons and four cylinders. Based on lean manufacturing principles, Messier-Dowty created an autonomous cell consisting of two lathes, a 3-spindle vertical machining center with an automatic 4th-axis indexing fixture and a 3½-axis horizontal machining center. "One of the flatbed lathes was set up for external work and the other was set up for internal work," Cerps said, who added that the arrangement greatly reduced setup time because the machines didn't have to be reconfigured individually to handle those operations. "The guys in the cell received cross training, employed pull systems and followed all the rules of Kanban," he added. In addition to speeding throughput, the work also helped assure part-to-part consistency by simplifying machine-to-machine transition of the parts.

The basic elements of an aircraft landing gear are the major support component, called the main or center fitting; the piston, or slide, that goes into the center fitting and provides the ability to lower and raise the gear; and the truck, or bogie beam, which is the crosspiece through which the axles run. The assembly also includes various small support struts, linkages and actuators. Until recently, ultrahigh-strength steels (such as 300-M, a high-tensile modified 4340 alloy) and aluminum alloys were the main materials employed. Now, to meet fuel economy-driven weight reduction requirements while maintaining strength, titanium and composites are being introduced. For example, the Boeing 787's main landing gear, produced by Messier-Dowty, includes ultrahigh-strength steel components, a titanium slider and braces made of composites. Messier-Dowty said it evaluated the manufacture of landing gear components from titanium matrix composites. Those materials exceed the performance of 300-M steel and titanium through a combination of strength, durability and light weight, but high material and manufacturing costs presently exclude their application.

Simultaneous Strategy

The time required to machine landing gear components, especially large parts, is remarkable. Mike Zambenedetti, senior application engineer for machining systems supplier MAG Cincinnati, Hebron, Ky., said a typical large landing gear component can be 150 " long and require processing on a series of five to 10 different machine tools. The high-strength alloy steel and titanium parts begin as rough forgings and machining times for each part are lengthy: total OD roughing can consume 200 hours, finishing can add 240 hours and ID operations may take 200 hours.

Courtesy of MAG Cincinnati

Top: A technician performs maintenance on a U5 single-spindle, 5-axis machining center from MAG Cincinnati. This configuration provides the flexibility and Z-stroke capacity required to access certain features on landing gear components.

Below: A titanium aircraft landing gear bogie beam fixtured for finishing operations in a U5 single-spindle, 5-axis machining center.

Mike Sess, MAG application engineering and vertical machine platform manager, said a key to maximizing throughput of the large parts is simultaneous machining. To facilitate that, MAG supplies multispindle, multiaxis profiling machines in which the spindles follow identical paths. In a 5-axis, 5-spindle profiler, for example, all five spindles move on the same X, Y, Z, A and B axes. "They are all carried in the same 'bathtub,' as we call it," Sess said. The spindles are programmed to work on five identical parts simultaneously, reducing the total time required to perform an operation on the parts by 80 percent compared to a single-spindle arrangement.

Courtesy of MAG Cincinnati

In a 5-axis, 5-spindle profiler supplied by MAG Cincinnati, all five spindles move on the same X, Y, Z, A and B axes, follow identical paths and are programmed to work on five identical parts simultaneously.

The machines optimize workhandling as well. A 5-spindle profiler can feature an X-axis stroke of 144 ', which, according to Zambenedetti, enables the manufacturer to set up zones where parts can be loaded or unloaded while other parts are being machined.

Illustrating the aerospace industry's demand for such machine tools, MAG Cincinnati is scheduled to deliver $70 million of equipment to the world's largest producer of titanium, VSMPO-Avisma, for a global "Landing Gear Manufacturing Center for Excellence" in Verkhnaya Salda, Russia. The order includes four multispindle titanium profilers and 12 HMCs, as well as workhandling and control equipment. The facility will produce landing gear components for the Boeing 787 and 777, the Airbus A380 and A350WXB and the Sukhoi Superjet 100. MAG Cincinnati's shipment follows its delivery of 10 titanium machining systems to VSMPO and its neighboring Boeing joint-venture company, Ural Boeing Manufacturing.

The size and capability of aerospace machining systems have evolved in tandem with changes in aircraft components, Sess said. In a response to growing use of titanium alloys for landing gears, enhancements to MAG profilers include spindles with torque output in the range of 2,000 lbs.-ft., application of the heavy-duty HSK 125 toolholders and design features that increase the machines' stiffness and rigidity.

As for smaller landing gear components, they benefit from mill/turn centers. Although those machine tools generally possess a smaller swing capacity than massive single-purpose equipment and therefore are limited to smaller parts, the centers reduce setup times "drastically because you can do multiple operations in one setup," said Peter Bhavra, tooling engineering specialist at Messier-Dowty in Toronto. Bhavra said the facility is adding two multitask machines to the mill/turn equipment it already has and plans to move currently produced parts to the new machines to optimize production and further improve consistency of part quality.

Tooling Package

Chris Mills, U.S. senior project manager of aerospace development for toolmaker Sandvik Coromant Co., Fair Lawn, N.J., said the unique features of and materials for landing gear components has prompted development of specialized aerospace tooling. For example, he said, Sandvik Coromant has assembled a package of tools for the key operations in landing gear machining, including deep-hole drilling, external profiling, 2-D and 3-D turn/milling, trepanning and helical interpolation. When manufacturing landing gear components from forgings, he said, "there is a huge amount of material that is removed," adding that when machining is completed, often just 10 to 20 percent of the forging's original weight remains.

Mills said perhaps the most challenging operation is drilling deep, large-diameter holes. "Some of the holes down the middle of a component are over 1 ' in diameter and 6 ' in depth."

Courtesy of Sandvik Coromant

For deep-hole drilling operations on large landing gear components, Sandvik Coromant developed T-Max special drill heads for diameters from 100mm to 358mm. The heads are designed to work with high-pressure, high-volume coolant systems. To facilitate chip removal in deep bores, the coolant is routed to the cutting drill's cutting edges and then flows back through the drill body itself.

For large landing gear components, deep-hole drilling often is performed on specialized machines. To make deep holes with the special machines, Mills said Sandvik Coromant developed T-Max special drill heads for diameters from 100mm to 358mm. Exchangeable cartridges and shims enable the head to be adjusted to produce different diameters.

The heads work with high-pressure, high-volume coolant systems. Unlike the coolant path in a typical through-coolant tool, in which coolant flows through the drill tip and out of the hole past the outside of the drill shaft, in the big drilling heads the coolant is routed to the cutting drill's cutting edges and then flows back through the drill body itself to enhance chip removal from deep holes. To maintain concentricity, wear pads are situated on the drill's OD. The tendency of titanium to chemically combine with cutting tool materials dictates the wear pad design and compositions. "The wear pads need to be smooth, have good lubricity, and not have reaction at all with the material," Mills said.

Courtesy of Sandvik Coromant

Bores produced by deep-hole drilling usually require the machining of internal features. Special boring bars with antivibration packages, such as this TNS bar from Sandvik Coromant, cut productively at long depth-to-diameter ratios. This 8.66 "-dia. bar was employed to machine a 12 "-dia. bore 8 ' deep in a landing gear component made of 300-M alloy steel.

Bores produced when deep-hole drilling usually require various internal features. To produce these features with the desired precision at high depth-to-diameter ratios, "you need antivibration bars," he said. The toolmaker's TNS bars, for example, feature an internal devibration package consisting of a slug suspended in oil. Often, for added rigidity, such bars are made of carbide.

As an example of a typical application for devibration bars, Mills described a landing gear boring operation in 300-M steel that involved an 8.66 "-dia. bar machining a 12 "-dia. bore 8 ' deep. For roughing, the tooling was able to achieve a cutting speed of 305 sfm, a feed rate of 0.016 ipr and a 0.197 " DOC, and finishing at the same cutting speed, a 0.008- ipr feed and a 0.047 " DOC.

Tooled to Fit The Job

To improve throughput, some landing gear manufacturers purchase forgings with excess material removed in a process referred to as forging qualification. Qualification usually includes roughing and finishing internal cylinder bore features and selected key locating surfaces.

A supplier of qualified forgings, Ewart-Ohlson Machine Co., Cuyahoga Falls, Ohio, specializes in CNC machining of medium to large parts in both standard and exotic alloys for the aerospace, energy, steel and automotive industries. David Achauer, the shop's general manager, said landing gear customers come to Ewart-Ohlson for its combination of large boring mills, large-swing lathes, deep-hole drilling equipment and experience in processing large, difficult-to-handle parts. He described the company's business as "varying from fast, heavy material removal to precision machining, depending upon product requirements. One of our core competencies is machining large cylinders, pistons or tubes, including landing gear components."

The largest examples of forgings qualified at Ewart-Ohlson are approximately 130 " long and weigh about 12,000 lbs. Most of the parts are aircraft-grade high- tensile steel, such as 300-M, but the shop also machines titanium and aluminum. Qualification typically includes establishing end-product centerlines within the forging envelope, roughing and/or finishing a large percentage of deep bores and machining locating surfaces that allow landing gear manufacturers to locate the forging for profiling.

To drill, bore and form deep holes in the forgings, the shop fabricates much of its own tooling, including boring bars, carbide drilling and boring heads, form cutters and locating fixtures. Ewart-Ohlson uses specialty machines with the horsepower and torque required for maximum material-removal rates, high-pressure coolant to maintain tool life and fixturing and tooling that can achieve straightness over the length of the bore. The largest holes drilled in landing gear components are about 10 ' deep and 15 " in diameter.

Turning operations are performed on large, powerful machines such as a 200-hp SAFOP Leonard 1000/1800 lathe, which can swing parts up to 98.5 " in diameter (65 " over the cross slide), 21 ' long and weighing 40 tons. Counterweighting the large, eccentrically shaped workpieces is critical to spin the parts smoothly and hold diametrical and roundness tolerances of ±0.001 " over the length of a cylinder or piston.

Continuous Improvement

Likewise, Messier-Dowty's Toronto facility also regularly tests new tooling and processes to improve its end products. The tests don't occur in the course of regular production. "I have blocks of material and bar stock, or actual parts that for one reason or another may have been scrapped," Bhavra said. "I maintain those so we have an actual part to use if I am going to do some test cutting."

Bhavra described the shop's success in developing processes for machining Aermet 100, an ultrahigh-strength martensitic alloy steel developed by Carpenter Technology Corp., Wyomissing, Pa., specifically for military landing gear applications. The alloy has high-tensile strength, fracture toughness and resistance to fatigue, all characteristics that make it difficult to machine. "When we started, we were given guidelines from another shop that recommended using cobalt, nonindexable tools, cutting it at turtle speeds and using plenty of coolant," Bhavra said. Following development of its own machining methods, the shop now cuts the alloy with high-positive geometry indexable cutting tools, and sometimes without coolant. "There are certain things that are correct in the textbook, but when you are actually machining parts, it is totally the opposite," Bhavra said.

Aero Tolerances

Like many aerospace components, landing gears are machined to close tolerances. According to Bhavra, they are generally machined from ±0.03 " down to ±0.0005 " depending on fit, form or function. "Bores and faces where there are mating parts, bushings for high-tolerance pins and so forth, can go as tight as ±0.0005 "," he said. Some parts require 100 percent coordinate measuring machine inspection.

Messier-Dowty's Cerps noted that customers' specifications dictate that mating-part dimensions be met with cutting and grinding performed after heat treatment. For the high-tensile steels machined at the Toronto facility, post-heat-treatment hardness can be from 52 to 55 HRC.

To improve productivity, the shop may replace some grinding operations with hard turning. Parts requiring plating traditionally were hard turned and then ground before plating. Finish grinding followed the plating process. Now, Messier-Dowty wants to eliminate one of those steps. "We are trying to replace the preplate grinding with hard turning and then go straight to plating," Cerps said.

In a related coating development, Cerps said Messier-Dowty is progressively implementing an HVOF (High-Velocity Oxygen Fuel) process to replace hard-chrome applications. HVOF uses metal-ceramic powder sprayed at 3,000 km/hr. on landing gear components, where it consolidates to form a friction- and wear-resistant coating. The environmentally friendly process eliminates the use of hexavalent chromium in the hard-chrome plating process. HVOF is in use on several production programs throughout Messier-Dowty, including the A380 nose landing gear.

Cerps pointed out that today, top quality, ease of use, ease of maintenance and lowest possible cost are givens for any manufacturer. Likewise, common goals include manufacturing products that are as light, as small and as strong as possible. But landing gear has another requirement. Unlike many of an airplane's assemblies, the landing gear shows when the plane is on the ground. "It has to look good," Cerps said. CTE

About the Author: Bill Kennedy, based in Latrobe, Pa., is contributing editor for Cutting Tool Engineering. He has an extensive background as a technical writer. Contact him at (724) 537-6182 or by e-mail at [email protected].

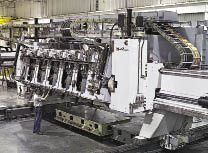

Courtesy of B. Kennedy

Multispindle profiling machines like this are part of machining systems packages being supplied by MAG Cincinnati to Russian titanium producer VSMPO-Avisma for a global "Landing Gear Manufacturing Center for Excellence" in Verkhnaya Salda, Russia.

Courtesy of MAG Cincinnati

Hard titanium alloys can cause microfractures on the thin, sharp edges of a solid-carbide drill point. AMAMCO says that on an "S-point" drill (left) the point corners (above and to the right of the lower coolant hole, below and to the left of the upper coolant hole) are rounded, or "S" shaped, to strengthen the cutting lip, compared to the corners on a standard cam-ground point drill (right).

Toolmakers' titanium tips

Some landing gear components are now being made with 5553 titanium alloy from VSMPO of Russia. That alloy, according to Chris Mills of Sandvik Coromant, "poses a lot of machining challenges." It is much higher in strength than the commonly used Ti6Al4V alloy, generates higher cutting temperatures and is more abrasive. With the same type of tools used for Ti6Al4V, "you reduce your cutting speed by 50 percent for 5553. So if you are cutting at 50 to 60 m/min. with 6Al4V, you are down to 25 to 30 m/min. with 5553," he said.

Mills noted that unlike nickel-base alloys that can workharden, the heat of machining has a minimal effect on titanium. "When we've looked at surface integrity, different cutting parameters, different edge preps or worn inserts, they have very little effect on the titanium materials the way that they do in nickel-base alloys. You're more concerned about getting the material off," he said.

The high value of titanium landing gear components may dictate the choice of a machining method. Mark Hatch, thread milling manager for toolmaker Emuge Corp., West Boylston, Mass., said thread milling offers advantages over tapping, especially when machining high-value aerospace parts. Thread milling—creating a thread via helical interpolation with a thread mill of smaller diameter than the hole—eliminates the possibility of tap breakage, which can ruin a partially processed part made of a high-cost material.

According to Brad Boisher, product support manager at AMAMCO Tool, Duncan, S.C., the correct tool geometry can facilitate machining titanium. He cited his company's "S-point" carbide drill as an example. Compared to a standard cam-ground point, the drill's corners inside the gash (where material is removed from the point's center to create the cutting edges at the drill's center) are rounded, or "S" shape (photo below). "The reason you round that angle is that titanium is very hard, and solid carbide is very brittle," Boisher said. "The sharper the angle is, the weaker the cutting lip is. It's all about strengthening the cutting lip." Without the rounding, "you'll get microfractures on those sharp corners."

He added that AMAMCO drills for titanium typically feature a narrow flute gullet and a thick drill core, design aspects for maximizing strength. For a 1 "-dia. drill for titanium, the core might comprise 40 percent of the drill tip, while for a drill designed for aluminum, the core might make up only 18 percent of the tip.

— B. Kennedy

Contributors

AMAMCO Tool

(800) 833-2239

www.amamcotool.com

Emuge Corp.

(800) 323-3013

www.emuge.com

Ewart-Ohlson Machine Co.

(888) 276-9171

www.ewart-ohlson.com

MAG Cincinnati

(859) 534-4600

cinmach.mag-ias.com

Messier-Dowty Inc.

(905) 683-3100

www.messier-dowty.com

Sandvik Coromant Co.

(800) 726-3845

www.coromant.sandvik.com/us