Will switching to carbide help?

Will switching to carbide help?

When battling ID grinding issues, The Grinding Doc explains why a carbide quill isn't always the best fix.

Dear Doc: We're ID grinding and suffering from deflection, taper and chatter. We're thinking of switching to a carbide quill. Will that help?

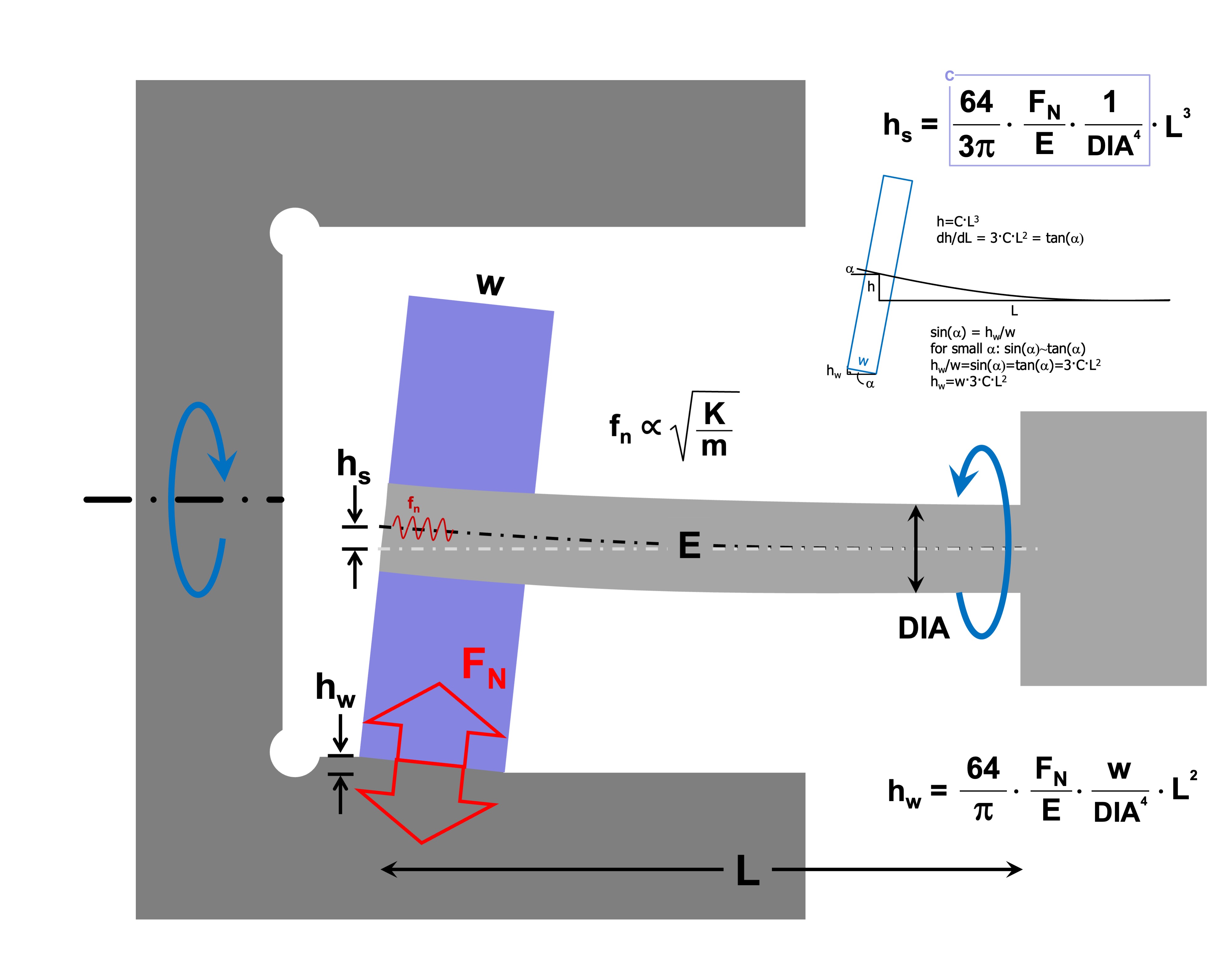

The Doc replies: Yes, it will help. Carbide has about three times the Young's Modulus, E, or stiffness, of steel. Therefore, you can expect about one-third the spindle deflection as shown in the figure for the formula for hs, spindle deflection.

But switching to carbide is not always my first choice. Why is that? It has to do with exponents. Deflection depends on E1 (quill stiffness), L3 (quill length) and DIA4 (quill diameter). Where will you get the most bang for your buck? Quill diameter (exponent 4), then quill length (exponent 3), then quill stiffness (exponent 1).

Let's say you've got a quill length of 50 mm. If you can get that down to 35 mm, that'll give you one-third the deflection: (35/50)3 = 0.343. That's the same as switching from steel to carbide.

Deflection is shown in the quill in cylindrical ID grinding. Exponents matter. Image courtesy of J. Badger

Look at diameter. It has an exponent of 4. Let's say you have a quill diameter of 30 mm. If you can increase it to 40 mm, you'll get about one-third the deflection: (30/40)4 = 0.316. Your diameter is only a third bigger, but you get three times the benefit. That's the power of exponents.

That spindle deflection is what causes taper, hw, and the "bell mouth" shape that we see in cylindrical ID grinding. How to deal with it? Reduce normal force (FN), increase quill diameter (DIA), reduce quill length (L), decrease wheel width (w), or increase quill stiffness (E). Pay attention to exponents to see which one has the most effect. (Don't forget that coolant hydroplaning can play a large roll in FN, even during spark-out.)

Finally, here's another reason I don't immediately jump into switching from steel to carbide: chatter. That spindle is going to bounce up and down at its natural frequency. (It always bounces at least a little.) We want it to bounce up and down at a high frequency to put those chatter marks closer together. Carbide has about double the density of steel. Unfortunately, that extra mass will decrease its natural frequency (see the equation) — not a huge amount but enough to counter at least some of the benefit of the increased stiffness. Yes, increasing the quill diameter will do the same — but only as DIA2, whereas the stiffness depends on DIA4. And length? Reducing it actually decreases mass and increases stiffness. Both of those increase the natural frequency.

Now it's getting messy — what to prioritize? I tend to prioritize diameter (particularly near the bearings where it's more important than near the wheel), then length, then normal force, then quill stiffness. Mostly. But not always. It depends on what's easiest to change and whether I'm battling deflection or chatter.

That's the simplified version. It becomes more complicated as stiffness and natural frequencies depend on numerous factors, not just what's happening in the quill. But as far as simplified concepts go, it works.