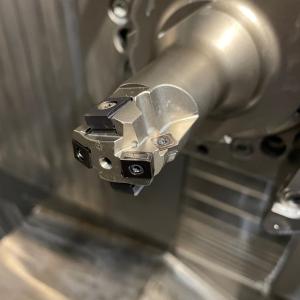

Boring

Ask The Experts: New Boring Solutions

Cutting Tool Engineering's July 2022 issue will focus on how shops can meet demand for stringent boring operations. Bores must be machined with micron accuracy and maintain critical tolerances in low- and high-volume manufacturing applications. New digital solutions in boring and machine tool systems are set to transform industrial production. To supplement this report online, CTE will address some of these solutions during its Ask The Experts webinar scheduled for 10 a.m. (CDT) on Wednesday, July 20th.