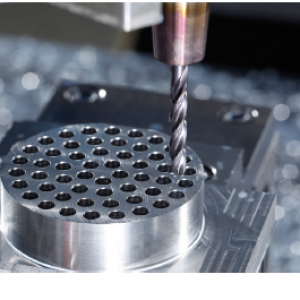

Drills

Perfomax -- when you need stability & versatility in holemaking

With a new re-engineered design, the Seco Perfomax indexable insert drill delivers higher drilling parameters and longer tool life as well as exceptional chip control and evacuation. The drill’s innovative features include new flute designs with special anti-friction surfaces and laser hardened fronts for added strength, stability and accuracy. Watch as it demonstrates its versatility through a series of holemaking operations in this video.

Learn more about the Seco Perfomax indexable insert drill here.

ARCH Cutting Tools is American manufacturing, serving the world

Cutting tool innovation often starts with collaborative problem solving at the spindle.