Grinding

CPX Linear: Blank preparation grinder

Capable of achieving a surface finish better than 0.2 Ra with run out of less than 2 microns, this four axes grinder for grinding tool blanks complements ANCA's full machine range. The CPX Linear has a large working envelope and powerful grinding spindles to achieve the highest precision and productivity for blank preparation in the market today. Using the pinch peel method of grinding, it offers the same strength, rigidity and thermal stability expected from an ANCA tool grinder.

The NXT Tool Grinder machine from Star

Cutting Tool Engineering recently visited the Star plant in Elk Rapids, Michigan, to learn more about Star SU's new NXT Tool Grinder machine, which made its debut at IMTS 2018. CTE Publisher Dennis Spaeth chats with Star Product Manager Aaron Remsing, Director of Engineering Roberta Wagner, Plant Manager Jason Walter, and Applications Engineer Jeremy Hubbard.

Learn more about the engineering process that went into developing the NXT in the latest Star SU Blog.

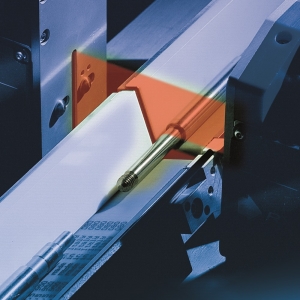

Episode 93: No hydroplaning in the grind zone

Cutting Tool Engineering's Ask the Grinding Doc columnist, Dr. Jeffrey Badger, addresses deflection problems where coolant meets the grind zone.