Milling

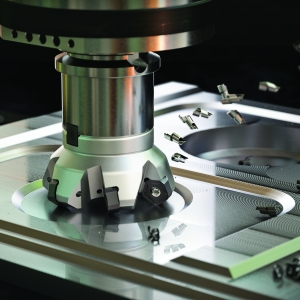

YG-1's New FM10 PNMU Face Milling Platform

YG-1 USA's new FM10 PNMU face milling platform, which is featured in this brief video demonstration, combines multi-corner face milling performance with high-feed capabilities. Click here for more information.

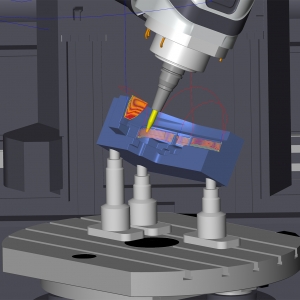

IMTS Partner Video with Autodesk's Inventor HSM Express and SwiftCARB

Watch 2D Adaptive clearing paired with SwiftCARB's coolant through AV series Rampmill rip through aircraft grade aluminum @ 375 IPM on a Haas VF2-SS. All of our tools are proudly made in the USA.