Milling

Three Decades of Expertise in High-Feed Milling

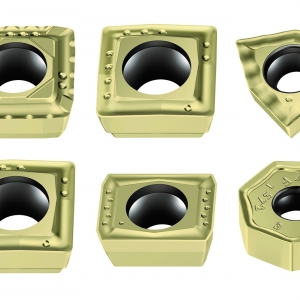

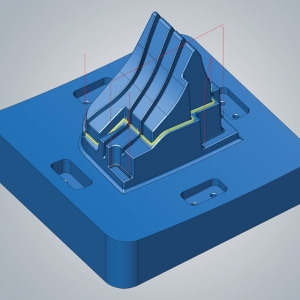

As a pioneer in the industry, Tungaloy has three decades of know-how developing the most efficient solutions for High-Feed Milling. Feed the speed with Tungaloy! The company has developed the widest range of High-Feed Milling tools and inserts, covering a spectrum of applications. HFM tooling options include the DoFeed, MillQuadFeed, DoTwistBall, DoFeedQuad, TungMeister, DoTripleMill and DoOcto.