Quality Control

Marposs monitoring solutions

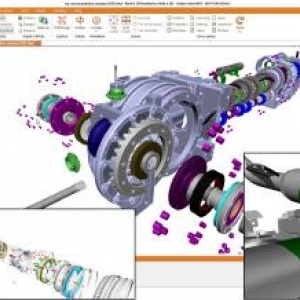

Marposs provides a full range of top-quality, innovative solutions for real-time tool and process monitoring and detection of machine conditions to improve machine efficiency, deliver higher quality and reduce costs. Analyze, safeguard and optimize production processes. Over 30,000 systems are in use worldwide and Industry 4.0-ready.

Marposs | www.marposs.com