Tool Coating

Drilling Ductile

Some coatings, such as TiAlN, enable dry machining when drill ductile cast iron, but coolant is desirable to help evacuate the material's small, curled chips. Flood coolant can be appropriate for holes less than 1.5 to 2 diameters deep, according to Bob Jennings, product manager for Ingersoll Cutting Tools, Rockford, Ill. Jennings noted that the toolmaker offers standard Qwik-Twist replaceable-point drills to drill up to 8 diameters deep.

Powdered metallurgy

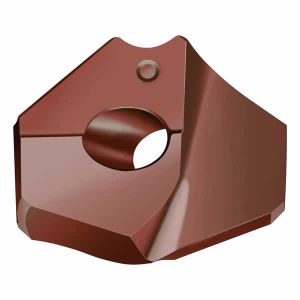

Watch a video presentation from Seco Tools LLC about the tools and techniques suggested for machining powdered metallurgy. The company reports that inserts with Seco Tool’s Duratomic CVD aluminum-oxide coating can work well for P/M components. The Duratomic technology promotes growth of coating crystals in certain crystallographic directions to improve coating properties.

Productivity Improvements Resulting from Coating Texturing

Don Graham, manager of turning products and education services at Seco Tools Inc., Troy, Mich., discussed "Productivity Improvements Resulting from Coating Texturing" during the Fast Track Seminar series hosted at the Cutting Tool Engineering booth during IMTS 2010.

PVD Coating

Platit Inc. recently hosted an open house in Libertyville, Ill., where the Switzerland-based toolcoating company presented cutting-tool and wear-part coating machines based on plasma-generating physical vapor deposition technology. The animation here offers an "insider's" view of the company's coating equipment.