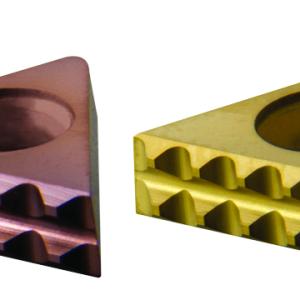

Modular Pull Clamping System from Fixtureworks

The cylindrical body design on this innovative clamping system is ideal for machining from 5 sides with no tool interference and no need for additional machining setup. It can be used as a mechanical zero point clamping system for quick fixture change with precise dual contact that provides 0.005 mm locating repeatability. Clamping screws are used with the modules for precise locating and clamping. Learn more