May 2010

Articles in this issue

Enabling product line expansion

END USER: The M.K. Morse Co., (800) 733-3377, www.mkmorse.com. CHALLENGE: Eliminate dirt and debris from machine coolant when grinding cermet-tipped saw blades…

Maintaining the productivity party

END USER: North America Clutch Corp., (414) 267-4000, www.noram-clutch.com. CHALLENGE: Lower manufacturing costs. SOLUTION: An automated turning center. SOLUTI…

Racking up ribs

END USER: Prospect Mold Inc., (330) 929-3311, prospectmold.com. CHALLENGE: Reduce the time needed to cut grooves in a large mold. SOLUTION: Replace EDMing with…

Leave it better than you found it

Machinist's Corner column for the May 2010 issue of Cutting Tool Engineering.

CAD/CAM belongs on the shop floor

Get with the Program column for the May 2010 issue of Cutting Tool Engineering.

Finessing fins

Part Time column for the May 2010 issue of Cutting Tool Engineering.

Brain food for the metalworking shop

Shop Operations column for the May 2010 issue of Cutting Tool Engineering.

Toolholder and tool balance

Machine Technology column for the May 2010 issue of Cutting Tool Engineering.

Fastest way to new business

Manager's Desk column for the May 2010 issue of Cutting Tool Engineering.

Air force

Is your shop like a clean room? It could be.

Turning nasty

Insert geometries for effectively turning high-temperature superalloys.

Not your father’s VMC

Advanced vertical machining centers provide performance and value.

Deep and steady

A long boring tool can cause vibration, so deep holes can be deep trouble. But several strategies can minimize vibration.

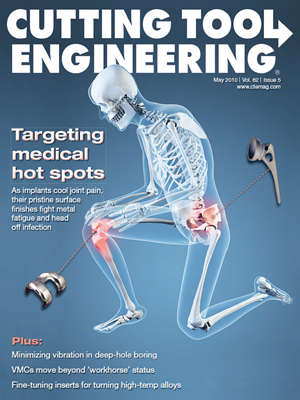

Surface finesse

Pristine finishes are pivotal for safe and effective orthopedic implants.