$2 million in metalworking equipment on loan to Montana State University

$2 million in metalworking equipment on loan to Montana State University

Montana State University students interested in crafting metals into machine parts will soon have access to a $2 million lathe that can cut spinning materials so precisely that its end products are measured in fractions of the width of a human hair.

Montana State University students interested in crafting metals into machine parts will soon have access to a $2 million lathe that can cut spinning materials so precisely that its end products are measured in fractions of the width of a human hair.

According to a story by Skip Anderson, MSU News Service, the lathe weighs about 37,000 pounds and is the size of a small bedroom. It is on indefinite loan from Los Alamos National Laboratory (LANL). The purpose of the loan is to provide MSU engineering and manufacturing students with experience using the high-precision instrument and to challenge students to design and build a prototype for a smaller, lighter lathe with the same high-precision capabilities, which LANL hopes to use to build parts to support the nation's nuclear readiness.

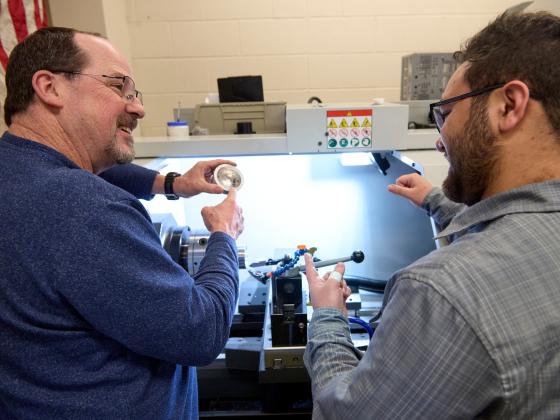

"This lathe is so big, it may take as many as eight people to assemble it once it arrives here on two semitrucks," said David Miller, a professor in MSU's Department of Mechanical and Industrial Engineering, which is part of the Norm Asbjornson College of Engineering. "This is a longstanding, unclassified project for the National Nuclear Security Administration, which is part of the U.S. Department of Energy."

The lathe is expected to be installed in MSU's Barnard Hall this spring.

Miller and his team of 20 current MSU students — one doctoral student, four master's students and 15 undergraduate students — will then continue designing a new lathe half the size and weight of the forthcoming hardware and equally precise, down to fractions of micrometers. To add to this challenge, the new lathe is expected to be made from mostly aluminum, a lightweight metal that flexes under stress, which can be problematic when precision matters.

"It needs to be smaller, lighter and just as precise," Miller said.

And precision is critical, given that the lathe Miller is tasked with designing will contribute to the manufacture of special nuclear materials for the country's nuclear readiness, Miller said.

Despite not having the heavyweight lathe just yet, the project has been underway for more than two years.

"We have been performing the same work without the big lathe by using our current lathes," Miller said. "The new lathe will simply provide the baseline for the most accurate system that could exist."

Over the past 24 months, LANL has hired six graduates from Miller's lab.

"LANL realized Montana State has talented students trained in these processes, and they are knowledgeable about issues and concerns relevant to LANL's needs," he said. "Then LANL started hiring more and more MSU students."

According to Miller, LANL has hired more than 40 students from MSU over the past five years.

"Given my interest in manufacturing engineering, I am seeking out job opportunities that involve metal manufacturing processes," said Michael Strand, a mechanical engineering major who is expected to graduate this May.

The senior from Selah, Washington, said he has gained valuable experience working on the metal-turning lathes at MSU, but none are as large, powerful or accurate as the one that will soon be installed.

"I have experience with a few different lathe machines as part of my student work in David Miller's lab," Strand said. "The lathe that the lab is receiving will differ in several ways from the ones I've operated. The new lathe can accommodate larger stock material, has greater rigidity and can perform manufacturing operations with greater precision than the ones we currently operate."

Strand hopes the new machine will be up and running before he graduates so he can gain experience with it, a valuable inclusion for a resume.

"Our students will have the ability to work with the gold standard of lathe technology," Miller said.