Building a giant telescope to look back further in time

Building a giant telescope to look back further in time

Imagine a beam of light traveling unimpeded for 13.5 billion light years, only to get deflected and distorted just before being captured by a telescope. That is something the builders of the Giant Magellan Telescope are working hard to avoid.

Imagine a beam of light traveling unimpeded for 13.5 billion light years, only to get deflected and distorted just before being captured by a telescope. That is something the builders of the Giant Magellan Telescope are working hard to avoid.

Photos courtesy of Giant Magellan Telescope Organization unless otherwise indicated

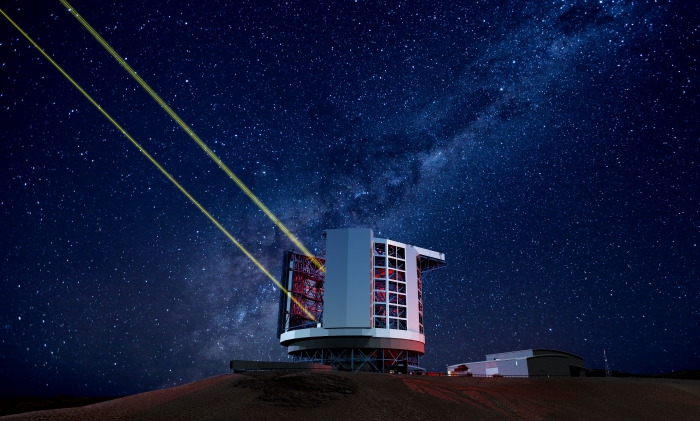

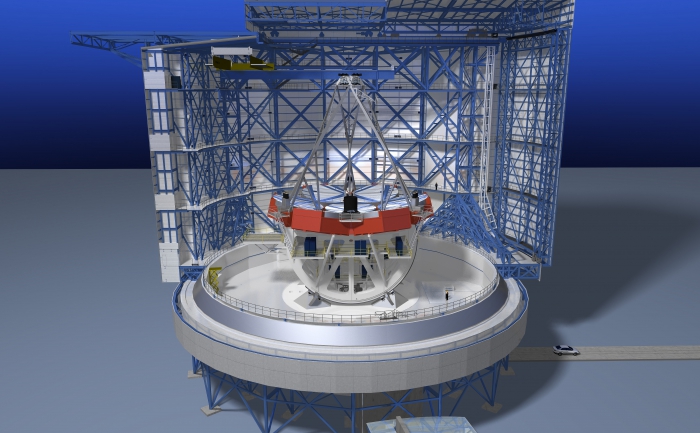

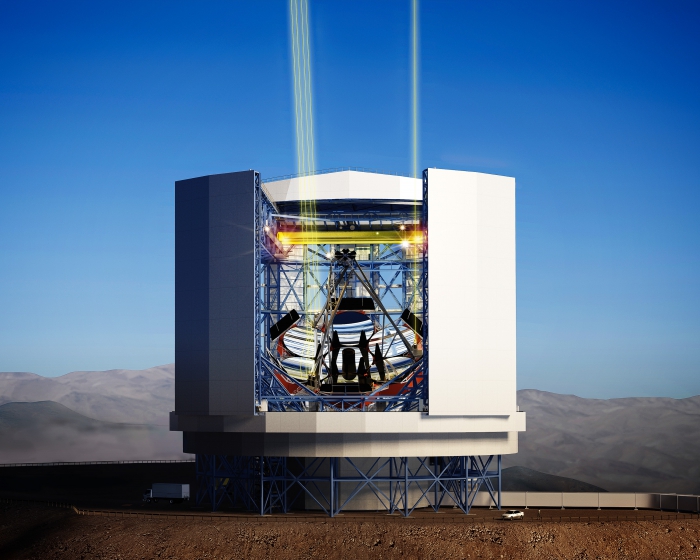

The GMT is poised to be the first "extremely large telescope" to begin operations, with a first-light target date of 2023, according to the Giant Magellan Telescope Organization Corp., Pasadena, Calif. The GMT will have an effective diameter for diffraction of 80' (24.5m) and probe the visible universe from an elevation of 8,200' (2,500m) at the Las Campanas Observatory in Chile.

"What we don't want to happen when that light finally gets in front of the telescope close to its dome is to get vastly distorted by hot air trapped inside the dome," said Patrick McCarthy, vice president of operations and external relations for GMTO.

He added that the telescope has adaptive optics that can fix some of the image distortion, but a much better approach is to never distort or otherwise damage the image. To help achieve that by ensuring the airflow coming up the mountain and approaching the telescope enclosure doesn't create any ripples in the atmosphere, GMTO is working with Boeing Research & Technology.

Therefore, the temperature variations of the air along the path of the light through the telescope needs to be maintained to ±0.1° C, McCarthy noted. "It really requires that we flush the air," he said, "and do so in a way that doesn't create a lot of turbulence. A great thing about working with the Boeing people is that they understand turbulence to a very deep level. Their job is dealing with turbulence over airfoils."

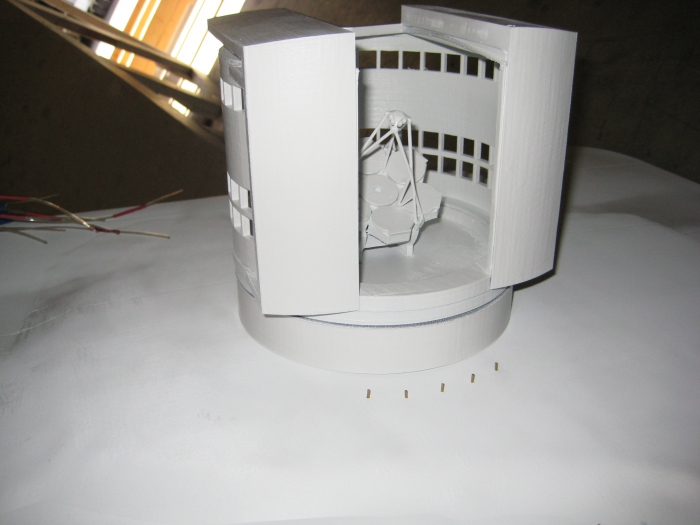

Boeing Research & Technology 3D-printed a 1/355-scale model of the telescope to help GMTO engineers determine the aerodynamic impact of the design features they are considering for all the elements of the telescope, said Bill Norby, senior manager for aerosciences at the company's St. Louis facility. Boeing employed a series of computational fluid dynamics studies of the model in a water tunnel to gather experimental data and validate its CFD modeling that is predicting the flow field.

Boeing Research & Technology employed a series of computational fluid dynamics studies of its 3D-printed telescope model in a water tunnel. Photo courtesy of Boeing Research & Technology

The model of the telescope enclosure, structure and seven primary mirrors are made of polylactite (PLA), which is a bioplastic made from corn, the secondary mirror assembly and support structure are titanium, and the ground terrain surface is ULTEM 9085.

One area of interest was the effect of the shape of the telescope enclosure near the base. "As the airflow is coming up the mountain and approaching the enclosure, the shaping of that has a really profound impact of the flow field right in front of the telescope aperture," Norby said. "One of the design intents, which has to be balanced with a number of different aspects, is avoiding churning up the warmer ground-layer air and throwing it up into the enclosure, where it can affect the optics."

Boeing developed thermal modeling tools to assist GMTO engineers as they proceed through the design process. "The thermal tools are intended to take into account the structural properties and the operating conditions that the telescope is expected to experience," said Abdi Khodadoust, engineering manager for Boeing Research & Technology at its Huntington Beach, Calif., facility. "The model is essentially built so that it has enough flexibility so that the GMT engineers can exercise and explore the operating envelope of the structure and the telescope."

These activities will allow the engineers to gather information and make informed decisions about the enclosure design and the operation of the telescope, Khodadoust added.

Boeing designed and built the model in St. Louis and tested it in Huntington Beach. "We went through a lot of iterations to optimize the shaping," Norby said.

Photo courtesy of Boeing Research & Technology

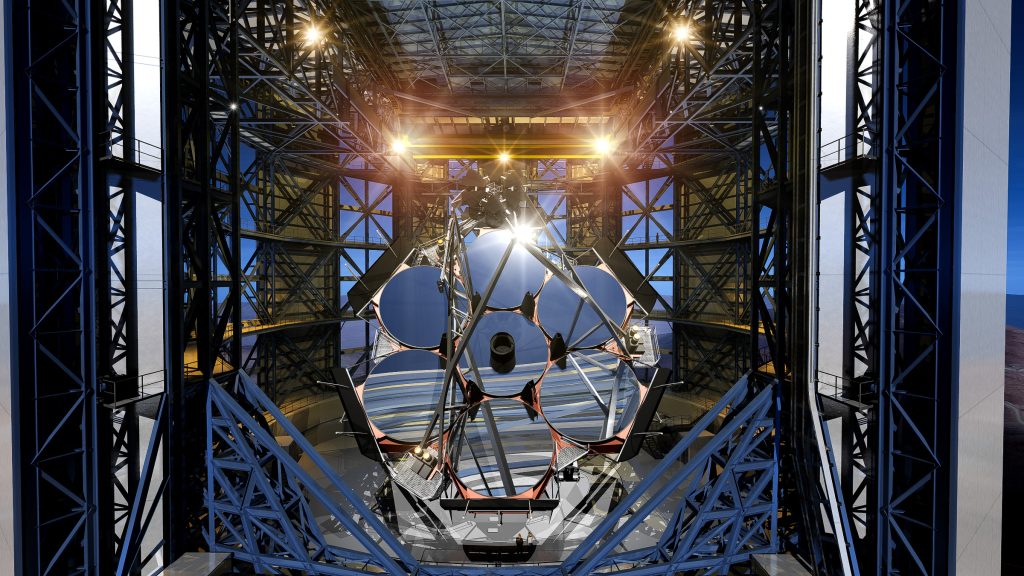

Looking at the more massive elements of the telescope's development, the seven primary mirrors, which each measure 27' (8.4m) in diameter, are being produced at the University of Arizona's Richard F. Caris Mirror Laboratory. According to GMTO, the challenge associated with making the large off-axis primary mirror segments was identified as the greatest technical risk to the program.

The mirrors are made of borosilicate glass, McCarthy said. The glass is melted in a mold that is mostly empty space to minimize weight. "We have, in essence, a honeycomb sandwich," he added.

Large grinding wheels that have diamonds embedded in a metal matrix are applied when roughing the mirrors, McCarthy explained. "We are talking about large surfaces and, in the beginning, we are removing a couple of cubic centimeters per minute."

The mirrors are then finished machined to impart a surface finish of about 100µm (0.0039") rms before loose abrasive is applied to achieve a 1µm rms finish. Polishing is then performed, typically with cerium oxide.

"Then it is less about removing material and much more about controlling the figures to go from 1 micron to 100 nanometers down to 20 nanometers," McCarthy said. "Then it becomes a process of measurement and metrology and very selective material removal."

Active figure control is achieved through forces applied to the rear factsheet of the mirror by hundreds of force actuators. The actuators push or pull on the mirror with carefully controlled forces to change the shape of the reflecting surface by displacements of less than 1 micron with an accuracy of roughly 50 nanometers. The actuators are force, rather than position, devices. The position and shape of the optical surface is measured using light from a star and an optical "Shack-Hartman" test. A screen with hundreds of holes produces images of sub-apertures of the mirror – each sub aperture is small enough to be diffraction-limited. The positions of these images are measured and their displacement from a uniform grid gives a measure of the slope of the mirror. These slope measurements are then integrated to determine the shape of the reflective surface. From the measured shape we can determine the forces needed to modify the mirror shape. The measurement-force feedback loop is run continuously and the forces are adjusted every 30 seconds to ensure that the mirrors produce sharp and well focused images all night long.

In addition to better understanding the properties of planets around other stars, cosmic chemistry, galaxy formation and evolution, and dark matter and energy, the Giant Magellan Telescope seeks to discover the first light and reionization—when the universe was no longer opaque. GMTO reports that some 400,000 years after the big bang, electrons and protons combined to form the first atoms. The universe remained dark for the next 50 to 100 million years, until it was lit up by energy released by the first stars, accreting black holes and galaxies.

"We want to look back to find that cosmic dawn, that era of first light," McCarthy said. "We don't know precisely what happened. That's part of the mystery."