Cutting tool orders hit $208.1M in June, narrowing YTD gains

Cutting tool orders hit $208.1M in June, narrowing YTD gains

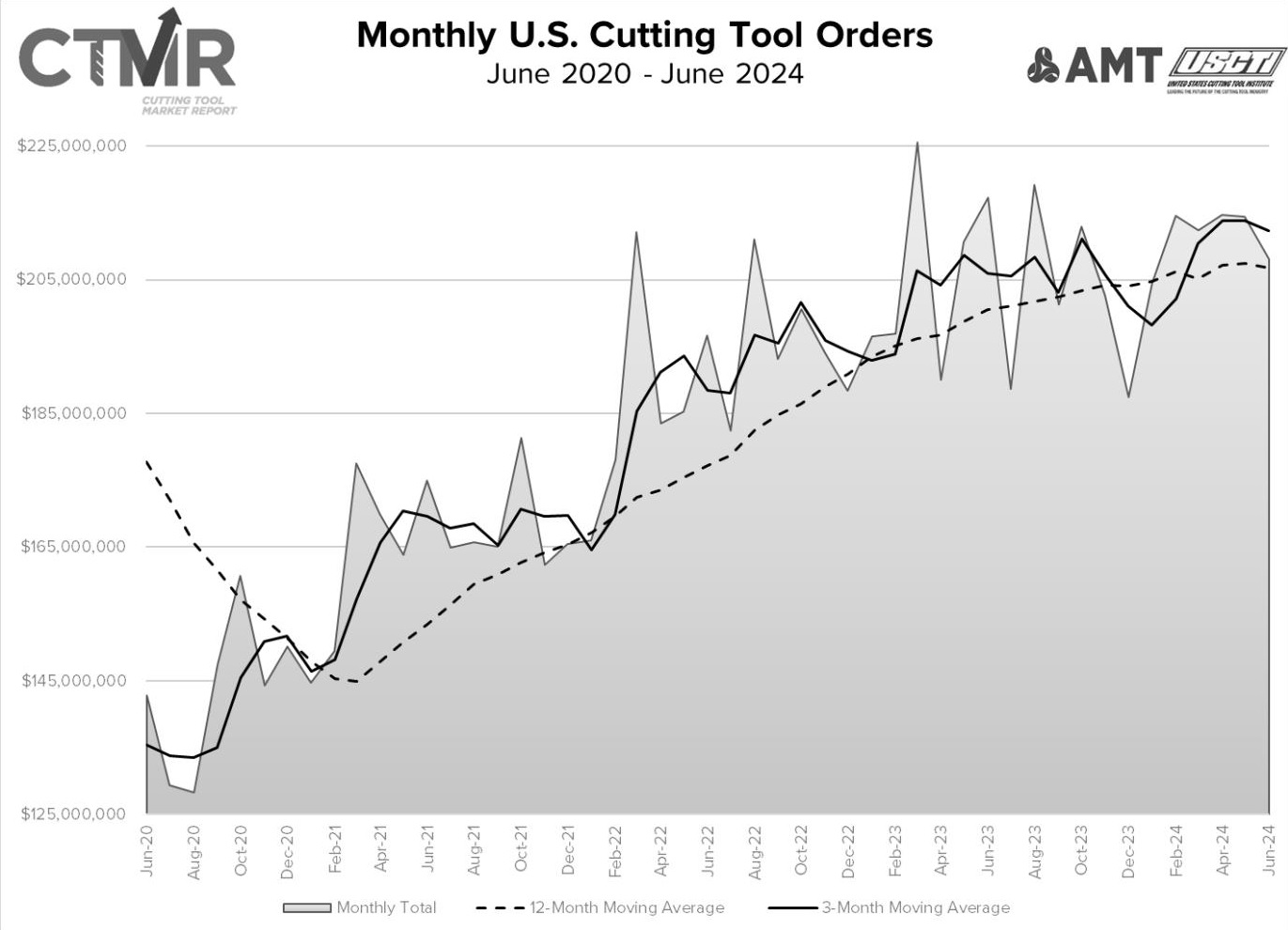

Shipments of cutting tools were $208.1 million in June 2024. Orders decreased 2.9% from May 2024 and were down 4.2% from June 2023. Year-to-date shipments totaled $1.27 billion, up 2.6% from shipments made in the first six months of 2023.

Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT – The Association For Manufacturing Technology and the U.S. Cutting Tool Institute (USCTI), were $208.1 million in June 2024.

Orders decreased 2.9% from May 2024 and were down 4.2% from June 2023. Year-to-date shipments totaled $1.27 billion, up 2.6% from shipments made in the first six months of 2023.

"While 2024 started on a positive note, we have seen significant stagnation in several markets utilizing cutting tools," said Steve Boyer, president of USCTI. "Aerospace has seen many challenges this year, and while we expect to see that market improve in 2025, it has impacted growth for 2024. Modest gains have been realized with orders for the automotive markets but have not fully offset some of the slides attributable to the aerospace industry. While tempering our enthusiasm for the second half of 2024, expectations for cutting tool order growth are still very positive for 2025."

Looking at the remainder of the year, Eli Lustgarten, president of ESL Consultants, said: "Cutting tool demand is likely to show further softness in the second half of 2024, driven by widespread inventory liquidation in many industries. While there are pockets of strength in markets such as government-financed infrastructure and data centers, the farm equipment sector will show dramatically lower production in the second half of 2024. Energy, construction, and mining sector output will decline. Heightened uncertainty also exists in automotive and commercial aerospace markets."

The Cutting Tool Market Report is jointly compiled by AMT and USCTI, two trade associations representing the development, production, and distribution of cutting tool technology and products. It provides a monthly statement on U.S. manufacturers' consumption of the primary consumable in the manufacturing process, the cutting tool. Analysis of cutting tool consumption is a leading indicator of both upturns and downturns in U.S. manufacturing activity, as it is a true measure of actual production levels.